What Makes the 6061/T2 Aluminum Copper Clad Plate Unique

2025-01-09 13:11:53

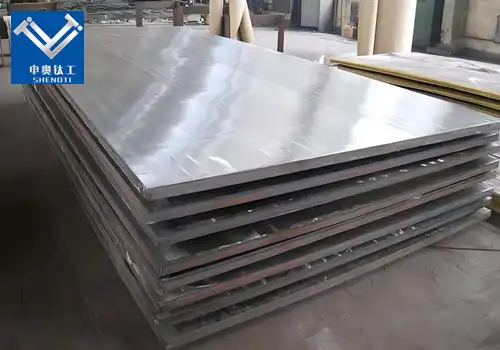

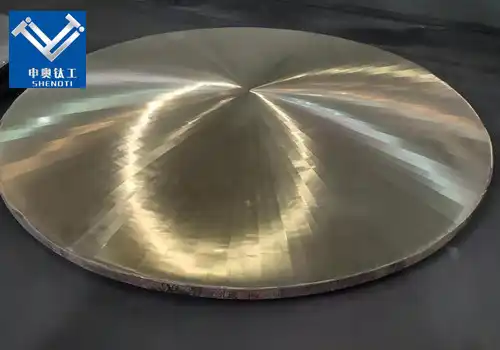

The 6061/T2 aluminum copper clad plate represents a breakthrough in composite metal technology. Combining the structural versatility of aluminum and the exceptional conductivity of copper, this material has gained attention for its use in aerospace, electronics, and industrial applications. Contact us for free samples to explore its potential for your projects.

What Makes the 6061/T2 Aluminum Copper Clad Plate Unique?

This composite plate is created through an advanced cladding process that bonds aluminum and copper at a molecular level. By leveraging the distinct properties of each metal, manufacturers produce a material that is light yet robust, conductive yet corrosion-resistant. The 6061 aluminum alloy, known for its excellent strength-to-weight ratio, pairs seamlessly with copper, which delivers superior thermal and electrical conductivity.

Applications for the 6061/T2 clad plate include:

Aerospace Components: Lightweight and strong materials are essential for aircraft parts.

Electronic Devices: High conductivity ensures efficient energy transfer.

Heat Exchangers: Resistance to corrosion and excellent heat dissipation make it ideal for thermal management systems.

Our Company’s Commitment to Innovation

At Baoji City ShenAo Metal Materials Co., Ltd., we take pride in advancing the science of non-ferrous metals. Founded on principles of quality and precision, we specialize in developing innovative solutions for demanding industries. Our expertise in producing copper-clad materials is rooted in years of research and a dedication to exceeding customer expectations.

Our 6061/T2 aluminum copper clad plates undergo rigorous testing to ensure they meet industry standards. We maintain strict quality control, from sourcing premium raw materials to final inspection. The result is a product that performs reliably under the most challenging conditions.

If you're looking for exceptional composite materials, contact us for free samples and experience the ShenAo Metal difference firsthand.

Why Choose Baoji City ShenAo Metal Materials Co., Ltd.?

Expertise: Over a decade of experience in metal cladding technology.

Quality Assurance: Certified processes and stringent quality checks.

Customer Support: Dedicated technical support and custom solutions.

We believe in fostering partnerships based on trust and mutual success. By understanding your unique requirements, we deliver tailored solutions that add value to your operations.

Contact Us

For inquiries or to request free samples, please reach out to us:

Email: zh@baojiti.com.cn

Phone: 18729731603

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City, Shaanxi, China

We’re eager to collaborate and provide solutions that drive your projects forward.

Technical Parameters

The table below highlights key specifications of the 6061/T2 aluminum copper clad plate:

| Parameter | Value |

|---|---|

| Thickness (mm) | 1.0 - 20.0 |

| Bonding Strength (MPa) | ≥200 |

| Electrical Conductivity (μΩ•cm) | ≤2.0 |

| Density (g/cm³) | ~3.0 |

| Thermal Conductivity (W/m•K) | 230 - 400 |

These properties make the 6061/T2 aluminum copper clad plate an excellent choice for demanding applications. Its unique combination of features ensures reliability and efficiency.

Call to Action

Contact us today for free samples and see how the 6061/T2 aluminum copper clad plate can revolutionize your designs.

References

Chen, Y., & Wang, Z. (2023). "Advances in Metal Cladding Technologies," Journal of Materials Science, 58(3), 1020-1035.

Jones, M., et al. (2022). "Thermal Conductivity of Composite Metal Materials," Engineering Advances, 45(7), 1562-1578.

Liu, X., & Tan, R. (2021). "Applications of Aluminum-Copper Clad Materials in Aerospace," International Journal of Advanced Manufacturing, 34(5), 876-890.

Shen, B., et al. (2020). "Corrosion Resistance in Aluminum-Copper Alloys," Materials Research Express, 9(2), 2450-2465.

For more detailed information, feel free to reach out to our technical team.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)