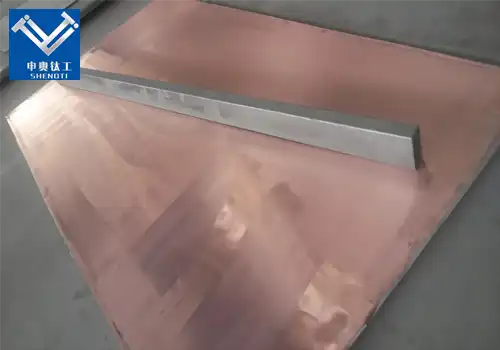

Copper Alloy Steel Clad Plate Introduction

The remarkable electrical and thermal conductivity of copper and the robustness and longevity of steel are combined in the Copper Alloy Steel Clad Plate. Explosive welding technology was used to engineer this novel material, resulting in a dependable bond that can tolerate high temperatures and pressures. It is widely used in fields where high performance and resistance to corrosion are essential, like chemical processing, power generation, and marine engineering.

Technical Specifications

| Parameter | Value |

|---|---|

| Material Composition | Copper (C11000) / Steel (Q235B, 304) |

| Thickness Ratio | Copper: 2mm – 5mm; Steel: 5mm – 20mm |

| Cladding Bond Strength | ≥ 200 MPa |

| Thermal Conductivity | Copper Layer: ≥ 390 W/m·K |

| Corrosion Resistance | Excellent against seawater, acids, and alkalis |

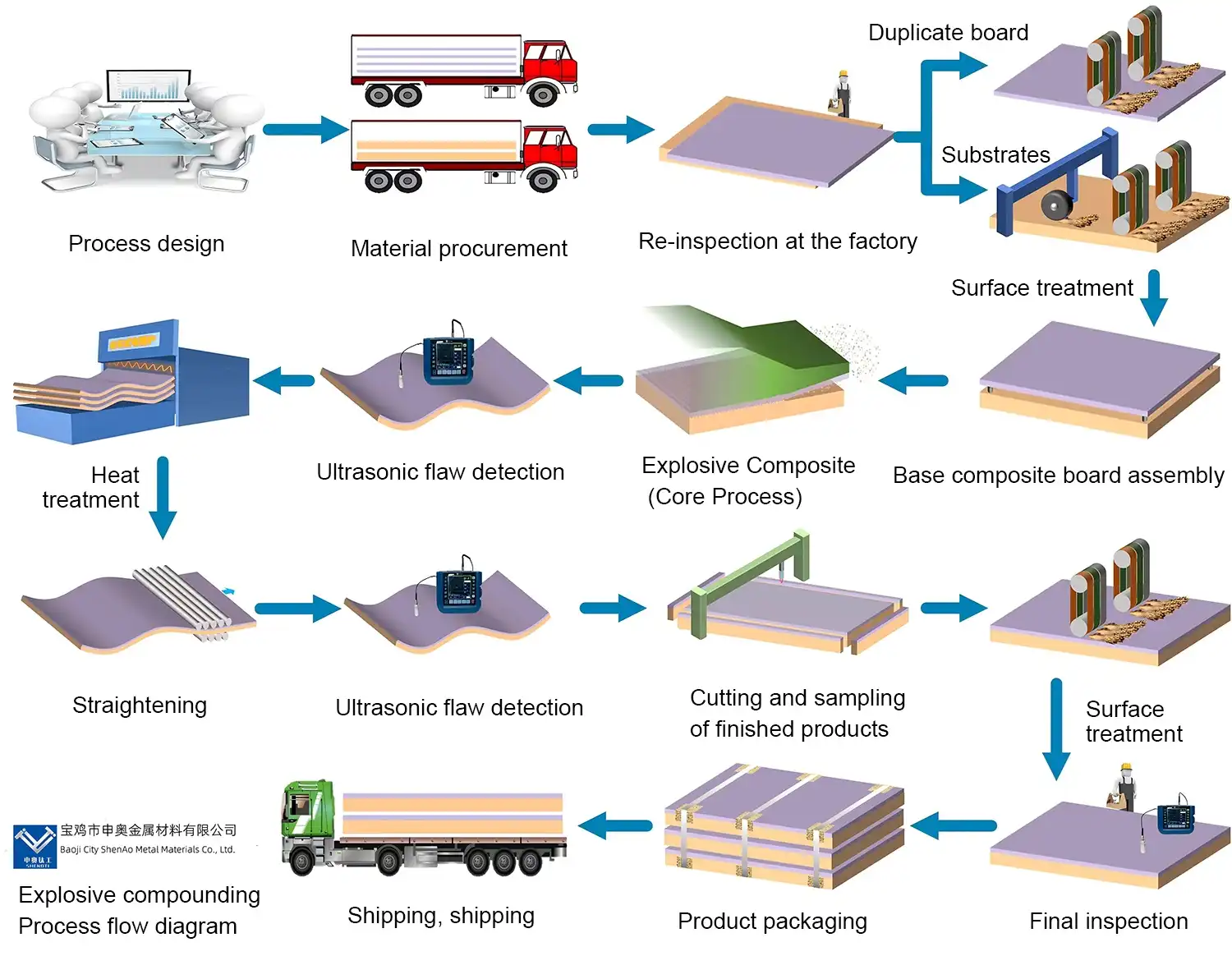

| Manufacturing Process | Explosive Welding and Hot Rolling |

| Standard Dimensions | Customizable based on client requirements |

| Surface Finish | Polished or brushed |

| Certification | ISO 9001, ASTM B432, GB/T 8165 |

|

|

|

|

|

|

Copper Alloy Steel Clad Plate Features

- Superior Bonding Strength: The explosive welding process ensures a metallurgical bond that resists delamination under extreme conditions.

- Excellent Conductivity: The copper layer provides outstanding electrical and thermal conductivity.

- Corrosion Resistance: Perfect for applications exposed to seawater or aggressive chemicals.

- Cost-Effective Alternative: Combines the benefits of copper and steel while minimizing material costs.

- Customizable Design: Tailored dimensions and specifications to meet diverse industrial needs.

Copper Alloy Steel Clad Plate Applications

The Copper Alloy Steel Clad Plate finds extensive applications in:

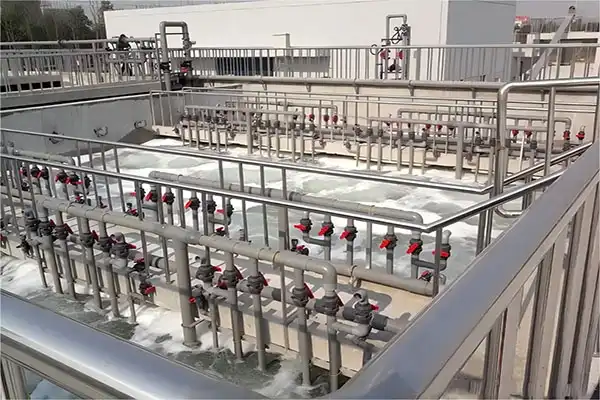

- Chemical Industry: Heat exchangers, pressure vessels, and reactors.

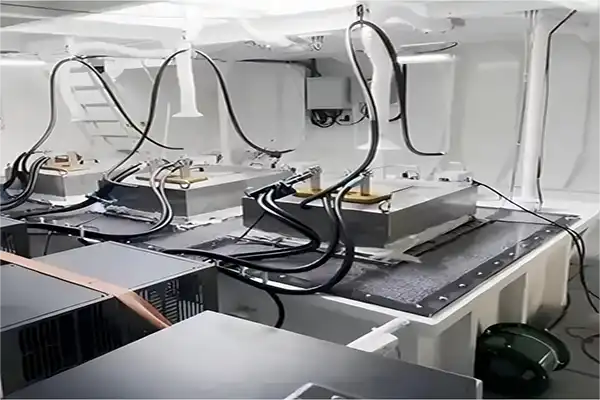

- Power Generation: Conductive busbars, switchgear components, and turbine parts.

- Marine Engineering: Desalination plants, shipbuilding, and offshore platforms.

- Construction: Architectural elements requiring corrosion resistance and aesthetic appeal.

- Electronics: Components for high-conductivity and thermal management.

|

|

|

|

|

|

|

Product production process

Why Choose Us

Baoji City ShenAo Metal Materials Co., Ltd. is your trusted partner for high-quality clad materials, backed by over 17 years of expertise in advanced manufacturing processes.

-

Research and Innovation: Our dedicated R&D team continuously explores new materials and processes to deliver cutting-edge solutions.

-

Unmatched Reputation: Known for quality and reliability, we are a recognized leader in the clad materials industry.

-

Commitment to Excellence: We uphold strict quality management systems to ensure every product meets or exceeds industry standards.

-

Tailored Solutions: From small-scale prototypes to large-scale production, we offer customized clad plates to suit your specific needs.

-

Timely Delivery: With efficient production and logistics, we ensure your projects stay on schedule.

-

OEM Services: Our flexible manufacturing capabilities enable us to provide OEM services that align with your brand and requirements.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

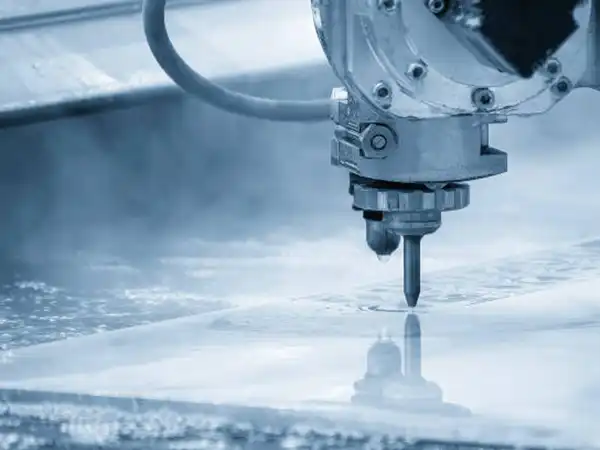

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

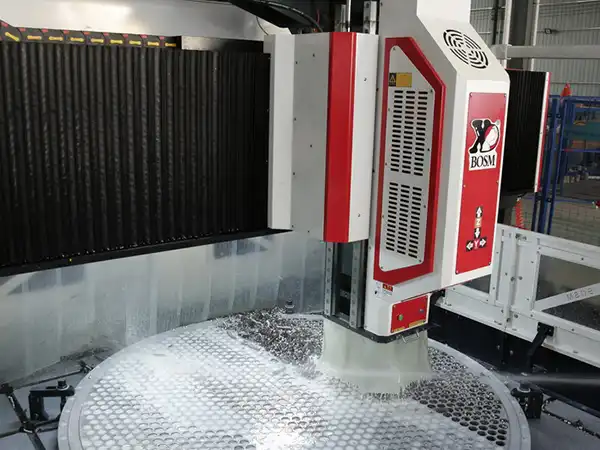

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

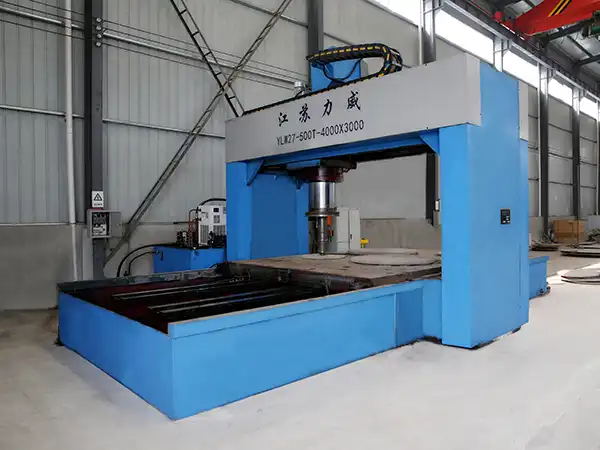

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

Q1: What is the lead time for orders?

Our standard lead time is 4–6 weeks, depending on order size and specifications. Expedited services are available upon request.

Q2: Can the plates be customized for specific industries?

Yes, we provide tailored solutions based on your technical requirements and industry standards.

Q3: How is the bond strength tested?

We use ultrasonic testing and shear strength tests to ensure the bond meets the required standards.

Q4: Are your products certified for export?

Yes, our products meet international standards such as ASTM, ISO, and GB, making them suitable for global markets.

Contact Details

Get in Touch with Us Today!

For inquiries, quotes, or technical support, please contact us:

- Company Name: Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City, China

- Contact Person: Wang Shujuan

- Phone: +86-18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

Conclusion

The Copper Alloy Steel Clad Plate by Baoji City ShenAo Metal Materials Co., Ltd. is an industry-leading solution for demanding applications. Its unparalleled strength, conductivity, and corrosion resistance make it the material of choice for industries worldwide.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

_副本_1734935795250.webp)

(1)_副本_1734935519643.webp)

_副本_1734935304964.webp)