Applications of Titanium Clad Plates in the Power Industry

2024-12-09 14:02:32

The power industry operates in some of the most challenging environments, with infrastructure exposed to extreme temperatures, pressures, and corrosive agents. Maintaining the efficiency and longevity of equipment is critical to ensure uninterrupted power generation. Titanium clad plates have emerged as a pivotal material in this sector, combining the corrosion resistance of titanium with the strength and cost-effectiveness of base metals like carbon steel or stainless steel. This article delves into the applications, benefits, and future prospects of titanium clad plates in the power industry.

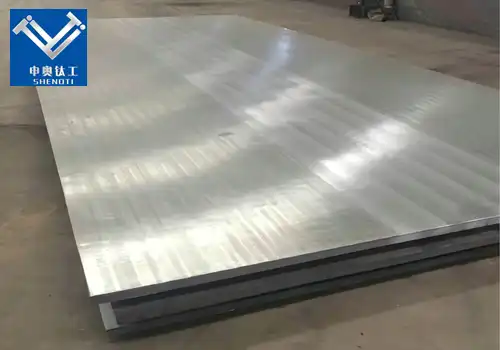

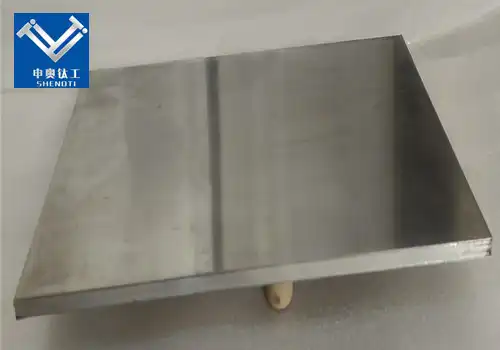

1. Overview of Titanium Clad Plates

Titanium clad plates are composite materials created by bonding a layer of titanium to a base metal, typically carbon steel or stainless steel. This composite combines the desirable properties of both materials:

Titanium Layer: Exceptional resistance to corrosion, high strength-to-weight ratio, and excellent thermal conductivity.

Base Metal: Provides structural strength and reduces overall material costs.

The combination makes titanium clad plates an optimal choice for power industry applications, where materials are subjected to harsh operating conditions.

2. Challenges in the Power Industry and How Titanium Clad Plates Address Them

Corrosion and Erosion

Power plants frequently deal with highly corrosive environments, including exposure to seawater, sulfur-containing gases, and acidic solutions. Titanium’s resistance to corrosion ensures the longevity of equipment, reducing maintenance frequency and costs.

Thermal Stress

Equipment in power plants must endure extreme thermal cycles. Titanium’s low thermal expansion and high thermal conductivity help maintain structural integrity under these conditions.

Cost Constraints

Pure titanium is expensive, making it impractical for large-scale use. Titanium clad plates balance performance and affordability by using titanium only where it’s needed most, while relying on a cost-effective base metal for structural strength.

Environmental Regulations

Stringent environmental standards require efficient flue gas desulfurization (FGD) and other pollution control systems. Titanium clad plates are ideal for these applications due to their ability to withstand acidic environments created during pollution control processes.

3. Key Applications of Titanium Clad Plates in the Power Industry

a. Flue Gas Desulfurization (FGD) Systems

FGD systems are used to remove sulfur dioxide (SO₂) from exhaust gases in coal-fired power plants. The process involves contact with sulfuric acid, chlorides, and abrasive particles, all of which can severely corrode equipment. Titanium clad plates are used in:

Absorber Towers: Provide corrosion resistance against acidic slurry.

Piping and Ductwork: Transport corrosive gases and liquids.

Heat Exchangers: Ensure efficient heat transfer while resisting fouling and scaling.

b. Condensers and Heat Exchangers

Condensers in power plants rely on seawater or freshwater for cooling, which exposes them to corrosive environments. Titanium clad plates are ideal for these applications due to their:

Superior resistance to seawater corrosion.

Ability to handle high thermal loads.

Long operational life, minimizing downtime.

c. Cooling Towers

Titanium clad plates are used in cooling tower components to resist corrosion from cooling water, which often contains chlorine and other aggressive agents.

d. Steam Turbines and Auxiliary Equipment

Steam turbines and their auxiliary systems often encounter high temperatures and steam containing impurities. Titanium clad plates are used for:

Turbine Casings: Withstand high pressures and corrosive steam.

Feedwater Heaters: Resist erosion and corrosion caused by high-temperature water.

e. Nuclear Power Plants

The demanding conditions in nuclear reactors require materials that can resist both radiation and corrosion. Titanium clad plates are used for:

Heat Exchangers and Steam Generators: Ensure safe and efficient heat transfer.

Storage Tanks: Hold radioactive waste without degradation.

Piping Systems: Transport corrosive fluids safely.

f. Renewable Energy Systems

In renewable energy sectors like geothermal and offshore wind power, titanium clad plates are utilized for:

Geothermal Heat Exchangers: Handle corrosive geothermal fluids.

Wind Turbine Components: Resist saltwater corrosion in offshore environments.

4. Benefits of Titanium Clad Plates in the Power Industry

Longevity and Durability

The titanium layer protects equipment from corrosion, significantly extending its lifespan even in the most aggressive environments.

Cost Efficiency

By using titanium only where necessary, titanium clad plates offer a cost-effective solution without sacrificing performance.

High Thermal and Mechanical Performance

Titanium’s excellent thermal conductivity and mechanical strength ensure that titanium clad plates perform reliably under extreme operating conditions.

Low Maintenance Requirements

The durability of titanium reduces the need for frequent maintenance and repairs, lowering operational costs and improving plant uptime.

Environmental Compliance

Titanium clad plates support compliance with environmental regulations by improving the efficiency and reliability of pollution control systems.

5. Production Technologies for Titanium Clad Plates

Explosive Welding

This technique creates a high-strength metallurgical bond between titanium and the base metal through controlled explosions. It is particularly effective for creating large, high-performance plates.

Hot Rolling

In hot rolling, the materials are bonded under heat and pressure, resulting in uniform and strong titanium clad plates.

Cold Rolling and Cladding

For applications requiring thinner plates or precise tolerances, cold rolling is used. This process ensures a smooth surface and excellent bonding quality.

6. Considerations When Using Titanium Clad Plates

Material Selection

The choice of base metal depends on the specific application. Carbon steel is typically used for structural strength, while stainless steel is preferred for additional corrosion resistance.

Fabrication and Welding

Specialized techniques are required to weld titanium clad plates. Improper handling can compromise the bond between layers.

Operating Environment

Factors such as temperature, pressure, and the composition of corrosive agents must be considered to ensure the optimal performance of titanium clad plates.

7. Future Trends and Innovations

Hybrid Clad Materials

Advances in material science may lead to the development of hybrid clad materials that combine titanium with other metals for specific power industry applications.

Automation in Production

Increased automation in manufacturing processes will improve the consistency, scalability, and affordability of titanium clad plates.

Expanded Use in Renewable Energy

As the power industry shifts toward cleaner energy sources, titanium clad plates will play a larger role in renewable energy systems.

Enhanced Recycling Techniques

Recycling technologies for titanium clad plates are likely to improve, reducing waste and further enhancing their sustainability.

8. Case Studies: Real-World Applications in the Power Industry

Coal-Fired Power Plant

A coal-fired power plant replaced traditional stainless steel components in its FGD system with titanium clad plates. This led to a 50% reduction in maintenance costs and significantly improved system reliability.

Nuclear Power Plant

In a nuclear facility, titanium clad plates were used in heat exchangers, ensuring safe and efficient operation for over 20 years without significant corrosion issues.

Offshore Wind Farm

Titanium clad plates were used in the cooling systems of offshore wind turbines, providing long-term resistance to saltwater corrosion and reducing downtime.

Conclusion

Titanium clad plates have revolutionized material selection in the power industry, offering an optimal combination of durability, performance, and cost-efficiency. Their versatility makes them indispensable in applications ranging from pollution control systems to renewable energy infrastructure.

As the power industry evolves to meet growing energy demands and stricter environmental regulations, the role of titanium clad plates is set to expand further. For companies seeking reliable, long-lasting solutions, investing in titanium clad plates is not just a choice—it’s a necessity for sustainable and efficient operations.

YOU MAY LIKE

_1735287684511.webp)

_1735893479791.webp)