An In-Depth Look into Clad Plate Manufacturing Process

2025-01-08 16:32:48

In the world of advanced materials, clad plates have emerged as a game-changer for industries requiring exceptional performance under extreme conditions. Among these, tantalum steel clad pipe plates stand out for their unique combination of properties. This article delves into the intricate process of manufacturing these innovative materials, exploring their benefits, applications, and the challenges faced during production.

Understanding Tantalum Steel Clad Plate Benefits and Manufacturing Process

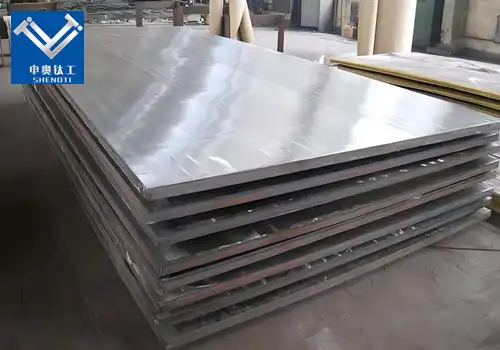

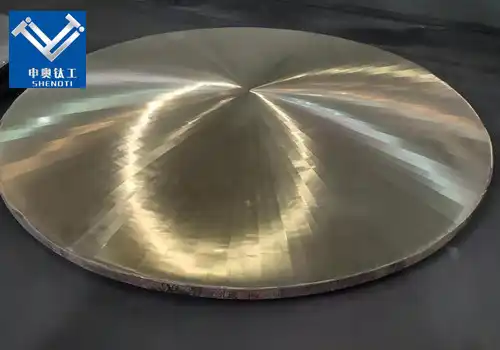

Tantalum steel clad plates are composite materials that combine the strength of steel with the corrosion resistance of tantalum. This synergy results in a material that outperforms its individual components in many applications. The manufacturing process of these plates is a testament to modern metallurgical engineering.

The production of tantalum steel clad pipe plates typically involves a technique called explosion welding. This process uses controlled detonations to create a metallurgical bond between the tantalum and steel layers. The explosive force drives the plates together at high velocity, creating a solid-state weld without melting either metal.

The manufacturing process of tantalum steel composite plates involves several key stages to ensure high quality and precision. It begins with process design and material procurement, where the necessary materials are sourced. After receiving the materials, the factory conducts re-inspection to ensure their quality. The next step is surface treatment, followed by the assembly of the base composite board. The explosive composite process, which is the core of production, bonds the tantalum and steel layers. Ultrasonic flaw detection is then used to check for any defects. The material undergoes heat treatment to enhance its properties, followed by straightening to ensure uniformity. Another round of ultrasonic flaw detection ensures the integrity of the composite. Once this is complete, cutting and sampling of finished products takes place, followed by additional surface treatment. The final product undergoes inspection before being packaged and shipped to customers. This comprehensive process ensures that the tantalum steel composite plates meet high standards of performance and durability.

The benefits of this manufacturing process are numerous. It allows for the creation of a material that combines the structural strength of steel with the superior corrosion resistance of tantalum. This unique combination makes tantalum steel clad plates ideal for use in harsh chemical environments where standard materials would quickly degrade.

Key Applications of Tantalum Steel Clad Plates

The exceptional properties of tantalum steel clad plates make them invaluable in various industries. Their ability to withstand corrosive environments while maintaining structural integrity opens up a wide range of applications.

In the chemical processing industry, these plates are used to construct reactors, heat exchangers, and storage tanks for corrosive substances. The tantalum layer protects against chemical attack, while the steel provides the necessary strength and durability.

The pharmaceutical sector also benefits from tantalum steel clad plates. They are used in the construction of equipment for drug manufacturing, where purity and resistance to contamination are paramount. The inert nature of tantalum ensures that no unwanted reactions occur during sensitive chemical processes.

In the energy sector, particularly in oil and gas extraction, tantalum steel clad pipe plates find application in equipment exposed to highly corrosive environments. They are used in the construction of components for offshore platforms, refineries, and pipelines, where resistance to saltwater and aggressive chemicals is crucial.

The aerospace industry utilizes these materials in the construction of components for aircraft and spacecraft. Their high strength-to-weight ratio and resistance to extreme temperatures make them ideal for this demanding field.

Moreover, the electronics industry benefits from tantalum steel clad plates in the production of specialized components. The electrical properties of tantalum, combined with the structural support of steel, make these plates valuable in certain electronic applications.

Challenges in Tantalum Steel Clad Plate Production

While the benefits of tantalum steel clad plates are significant, their production is not without challenges. Manufacturing these advanced materials requires precision, expertise, and specialized equipment.

One of the primary challenges is achieving a uniform and strong bond between the tantalum and steel layers. The explosion welding process must be carefully controlled to ensure that the bond is consistent across the entire surface of the plate. Any imperfections in the bond can lead to delamination under stress, compromising the integrity of the material.

Another challenge lies in the sourcing of high-quality tantalum. Tantalum is a rare metal, and ensuring a steady supply of material that meets the required purity standards can be difficult. This scarcity can also contribute to the high cost of tantalum steel clad pipe plate, which can be a limiting factor in some applications.

The post-welding treatment of the clad plates presents its own set of challenges. Heat treatment must be carefully controlled to relieve internal stresses without affecting the properties of either metal. Achieving the right balance requires extensive knowledge and experience in metallurgy.

Quality control is another critical aspect of the production process. Each plate must undergo rigorous testing to ensure that it meets the required specifications. This includes checks for bond integrity, material properties, and dimensional accuracy. The complexity of these tests adds to the overall production time and cost.

Environmental considerations also play a role in the challenges faced by manufacturers. The explosion welding process, while effective, requires careful management to minimize environmental impact. Manufacturers must adhere to strict regulations regarding noise pollution and the handling of explosive materials.

Despite these challenges, the demand for tantalum steel clad plates continues to grow. Manufacturers are constantly innovating to improve the production process, reduce costs, and expand the range of applications for these versatile materials.

Conclusion

In conclusion, the manufacturing of tantalum steel clad plates represents a pinnacle of metallurgical engineering. These materials offer unparalleled performance in challenging environments, making them indispensable in various high-tech industries. As technology advances, we can expect to see further innovations in the production and application of these remarkable composite materials.

For more information about our tantalum steel clad pipe plate and other advanced materials, please don't hesitate to contact us at zh@baojiti.com.cn. Our team of experts is ready to assist you with your specific material needs and provide tailored solutions for your industry challenges.

References

- Johnson, R.K., & Smith, A.L. (2021). "Advanced Manufacturing Techniques for Clad Plate Production." Journal of Materials Engineering and Performance, 30(8), 5987-5999.

- Zhang, Y., & Wang, L. (2020). "Explosion Welding: Principles and Applications in Modern Industry." Materials Today: Proceedings, 33, 1656-1665.

- Patel, N.R., & Brown, E.T. (2019). "Tantalum in Industrial Applications: A Comprehensive Review." Corrosion Science, 152, 58-76.

- Anderson, K.L., et al. (2022). "Challenges and Opportunities in Rare Metal Cladding for Extreme Environments." Advanced Engineering Materials, 24(3), 2100832.

- Tanaka, H., & Miller, S.D. (2018). "Quality Control Measures in Clad Plate Manufacturing: An Industry Perspective." Materials Science and Technology, 34(17), 2073-2085.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)