Introduction To Copper aluminum transition plate

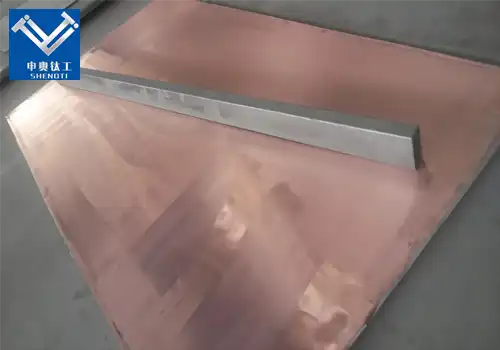

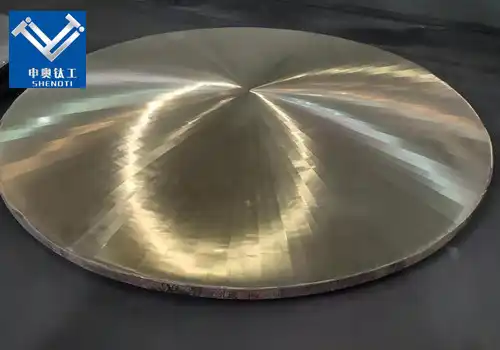

In a variety of industrial applications, the Copper Aluminum Transition Plate is a cutting-edge composite material created to close the gap between copper and aluminum components. For industries like power transmission, electronics, and chemical processing, this plate is crucial because of its high conductivity and resistance to corrosion.

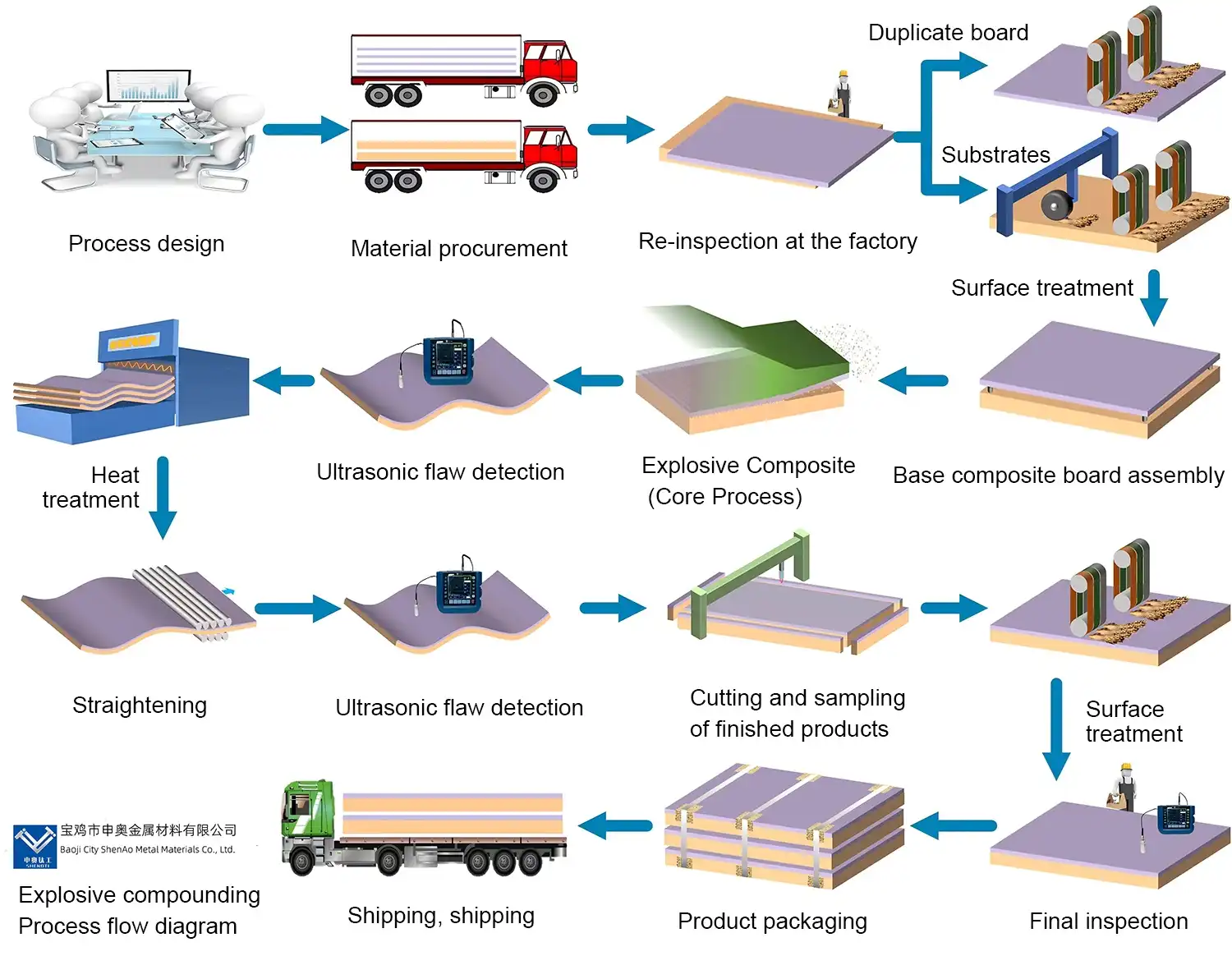

The copper aluminum transition plate ensures dependable performance and a longer service life by utilizing cutting-edge explosive welding technology to provide seamless integration. Whether you need materials that can endure harsh environmental conditions or want to increase the efficiency of electrical connections, our products offer outstanding value and performance.

Technical Specifications

| Specification | Details |

|---|---|

| Material Composition | Copper: 99.9% purity, Aluminum: 99.7% purity |

| Thickness Range | Copper: 1–10 mm, Aluminum: 3–20 mm |

| Width | Up to 1500 mm |

| Length | Customizable, up to 3000 mm |

| Bonding Technology | Explosive welding |

| Conductivity | Copper: > 95%, Aluminum: > 60% IACS |

| Corrosion Resistance | Excellent in acidic, alkaline, and marine environments |

| Operating Temperature | -50°C to 300°C |

| Certification | ISO 9001, ASTM B898 |

|

|

|

|

|

|

Product Features

- High Conductivity: Ensures optimal electrical performance with minimal energy loss.

- Corrosion Resistance: Resistant to oxidation, marine environments, and chemical exposure.

- Durable Bonding: Advanced explosive welding guarantees strong adhesion between copper and aluminum layers.

- Lightweight Design: Aluminum’s lightweight nature reduces overall component weight without compromising strength.

- Customizable Dimensions: Available in various sizes to meet diverse application needs.

- Cost-Effective: Combines the economic benefits of aluminum with the superior conductivity of copper.

Applications

Electrical Power Systems

- Switchgear Connections: Supplying switchgear with safe and dependable electrical connections, which are essential for managing and safeguarding electrical circuits in high-voltage systems.

- Transformer Windings: Providing outstanding mechanical strength and conductivity for transformer windings, guaranteeing effective power transfer and reducing energy loss.

- Busbars and Terminals: Perfect for dispersing massive electrical power among systems, reducing energy loss, and preserving robustness in high- and low-voltage applications.

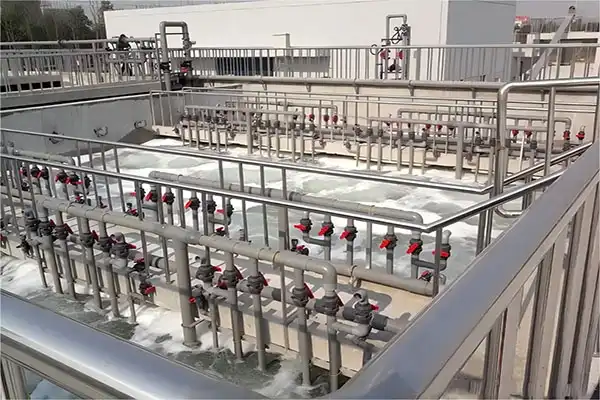

Chemical Processin

- Heat Exchangers: They are the perfect material for heat exchangers because of their high thermal conductivity, which increases the effectiveness of heat transfer operations in chemical plants.

- Electrolytic Cell Components: They are appropriate for use in electrolytic cells, which are crucial in a variety of electrochemical processes like metal plating and chlorine production, due to their exceptional electrical conductivity and corrosion resistance.

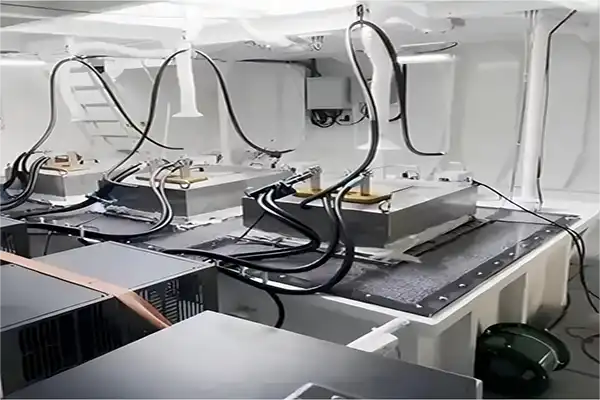

Marine and Shipbuildin

- Corrosion-Resistant Electrical Components: Perfect for electrical components exposed to seawater, providing long-lasting protection against corrosion, which is critical for the reliability of marine electrical systems.

- Structural Elements: Their strength and corrosion resistance make them ideal for structural applications in ships and other marine vessels, ensuring long-term durability and safety in challenging maritime environments.

Automotive and Aerospac

- Lightweight Electrical Connections: Ideal for creating lightweight electrical connections in vehicles and aircraft, reducing overall weight without compromising electrical performance.

- Hybrid Material Solutions for Energy Efficiency: By fusing the advantages of copper and aluminum, these materials enhance energy efficiency and can be used in hybrid material solutions that boost performance and fuel economy in aerospace and automotive applications.

Renewable Energy

- Solar Panel Connectors: Because of these plates' superior conductivity and resistance to corrosion, solar panel systems use them to ensure dependable and durable electrical connections.

- Wind Turbine Components: Used in wind turbines to provide durable, high-performance components that can withstand extreme weather conditions while contributing to efficient energy generation in renewable energy systems.

|

|

|

|

|

|

|

Product production process

Why Choose Us

- Research and Innovation: Our technical team continuously explores new processes to enhance material performance and application scope.

- Excellent Reputation: With over 17 years of expertise, we’ve earned the trust of global clients through consistent quality and outstanding service.

- Striving for Excellence: Our rigorous quality management ensures each product meets the highest standards, tailored to your needs.

- Customized Services: We provide bespoke solutions for diverse applications, ensuring that every product aligns with your specific requirements.

- Timely Delivery & Reliable Support: Fast response times and dedicated after-sales service ensure a seamless experience for our clients.

- OEM Services: Partner with us for branded solutions that align with your business goals.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

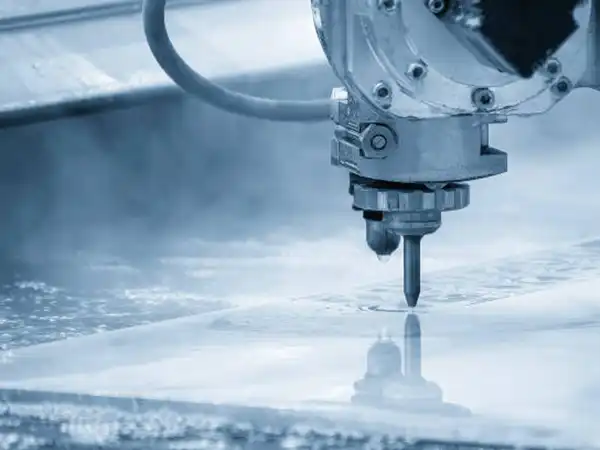

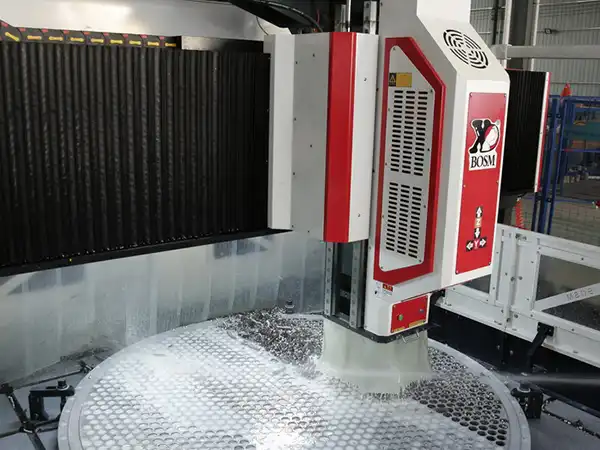

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

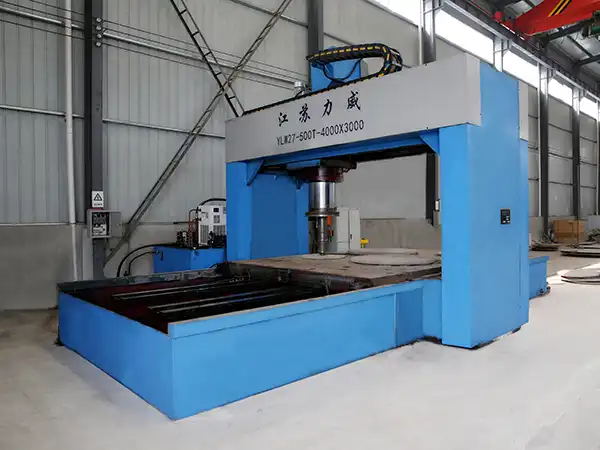

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

-

What is the lifespan of the Copper Aluminum Transition Plate?

With proper installation and usage, the lifespan exceeds 20 years, even in harsh environments.

-

Can dimensions be customized?

Yes, we offer fully customizable dimensions to suit your project requirements.

-

How does explosive welding improve performance?

Explosive welding creates a strong metallurgical bond without altering the individual properties of copper and aluminum.

-

Is the product certified?

Yes, our Copper Aluminum Transition Plate is ISO 9001 and ASTM B898 certified.

Contact Us

Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

- Contact Person: Wang Shujuan

- Phone: +86-18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

We’re here to provide tailored solutions for all your metal material needs. Let us know how we can support your business today!

YOU MAY LIKE

_副本_1734935795250.webp)

_副本_1734935851207.webp)

(1)_副本_1734935519643.webp)

_副本_1734935304964.webp)