What is a clad plate used for?

2025-01-08 16:29:10

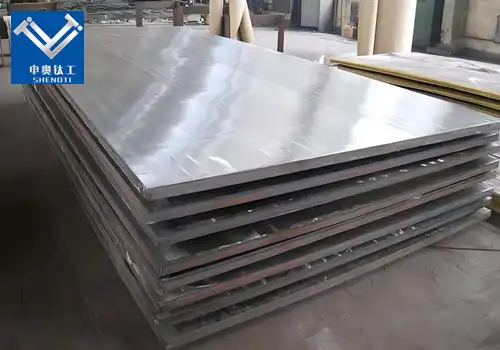

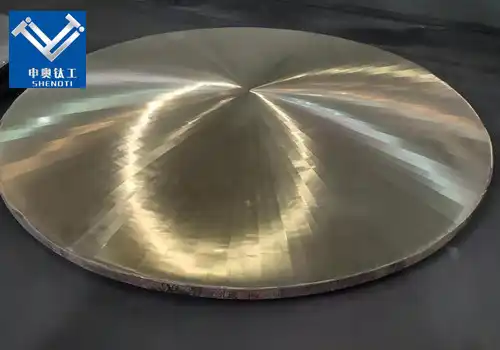

Clad plates, particularly titanium clad carbon steel plates, have revolutionized various industries with their unique combination of properties. These innovative materials offer a perfect blend of strength, corrosion resistance, and cost-effectiveness, making them indispensable in numerous applications. This article delves into the world of clad plates, focusing on titanium clad carbon steel plates, their applications, benefits, and how they enhance durability in various settings.

Top Applications of Titanium Clad Carbon Steel Plates

Titanium clad carbon steel plates have found their way into numerous industries due to their exceptional properties. Let's explore some of the top applications where these versatile materials shine:

Chemical Processing Industry

In the chemical processing industry, titanium clad carbon steel plates are extensively used for manufacturing reactors, heat exchangers, and storage tanks. These plates provide excellent resistance to corrosive chemicals while maintaining the structural integrity required for high-pressure operations.

Oil and Gas Sector

The oil and gas industry relies heavily on titanium clad plates for various applications. These include:

- Offshore platforms

- Subsea equipment

- Pipelines

- Pressure vessels

The combination of titanium's corrosion resistance and carbon steel's strength makes these plates ideal for withstanding harsh marine environments and high-pressure conditions.

Desalination Plants

Desalination plants benefit greatly from the use of titanium clad carbon steel plates. These plates are used in the construction of evaporators, heat exchangers, and other critical components that come into contact with highly corrosive seawater.

Power Generation

In power plants, particularly those using geothermal or nuclear energy, titanium clad plates find applications in heat exchangers, condensers, and other equipment exposed to corrosive fluids or high temperatures.

Aerospace Industry

The aerospace industry utilizes titanium clad carbon steel plates in various components where a combination of lightweight properties and high strength is crucial. These include structural elements and parts exposed to extreme temperatures.

Why Choose Titanium Clad Plates for Corrosion Resistance?

Corrosion resistance is one of the primary reasons why industries opt for titanium clad carbon steel plates. Let's delve into the factors that make these plates an excellent choice for corrosion-resistant applications:

Superior Corrosion Resistance of Titanium

Titanium possesses inherent corrosion resistance due to its ability to form a stable, protective oxide layer on its surface. This layer, known as titanium dioxide, provides exceptional protection against various corrosive environments, including:

- Seawater

- Chlorides

- Acids

- Oxidizing agents

By using titanium as the cladding material, the plates benefit from this superior corrosion resistance.

Cost-Effective Solution

While pure titanium offers excellent corrosion resistance, it can be prohibitively expensive for large-scale applications. Titanium clad carbon steel plates provide a cost-effective alternative by combining the corrosion resistance of titanium with the strength and affordability of carbon steel.

Versatility in Corrosive Environments

Titanium clad plates can withstand a wide range of corrosive environments, making them suitable for diverse applications. From acidic chemical processing to saltwater exposure in marine environments, these plates maintain their integrity and performance.

Long-Term Performance

The corrosion resistance of titanium clad plates translates to long-term performance benefits. Equipment and structures made with these plates require less maintenance, have longer lifespans, and experience fewer shutdowns due to corrosion-related issues.

Resistance to Pitting and Crevice Corrosion

Titanium's resistance to pitting and crevice corrosion makes it particularly valuable in applications where these forms of localized corrosion can be problematic. This property ensures the integrity of the clad plate even in challenging environments.

How Titanium Clad Carbon Steel Plates Enhance Durability

The combination of titanium and carbon steel in clad plates results in a material that offers enhanced durability compared to either material alone. Let's explore how these plates contribute to improved durability in various applications:

Synergy of Strength and Corrosion Resistance

Titanium clad carbon steel plates leverage the strengths of both materials:

- Carbon steel provides excellent mechanical strength and structural integrity

- Titanium offers superior corrosion resistance and chemical inertness

This synergy results in a material that can withstand both mechanical stresses and corrosive environments, enhancing overall durability.

Resistance to High-Temperature Environments

Titanium clad carbon steel plates exhibit excellent resistance to high-temperature environments. The titanium layer maintains its corrosion resistance at elevated temperatures, while the carbon steel substrate provides the necessary strength. This combination makes these plates ideal for applications in industries such as chemical processing and power generation, where high temperatures are common.

Improved Fatigue Resistance

The layered structure of clad plates contributes to improved fatigue resistance. The titanium layer helps distribute stresses more evenly, reducing the likelihood of fatigue-related failures. This property is particularly valuable in applications subject to cyclic loading or vibrations.

Resistance to Erosion-Corrosion

In environments where both erosion and corrosion are concerns, titanium clad plates offer superior protection. The titanium layer resists corrosion, while its hardness provides resistance against erosive forces. This dual protection is crucial in applications such as slurry handling in mining operations or high-velocity fluid flows in chemical processing.

Long-Term Cost Savings

The enhanced durability of titanium clad carbon steel plates translates to significant long-term cost savings. By reducing the need for frequent replacements, maintenance, and downtime, these plates offer a more economical solution over the lifecycle of equipment or structures.

Customizable Thicknesses

Titanium clad plates can be manufactured with varying thicknesses of titanium and carbon steel layers. This customization allows for optimized performance in specific applications, balancing corrosion resistance, strength, and cost considerations.

Weldability and Fabrication

Despite their composite nature, titanium clad carbon steel plates maintain good weldability and can be fabricated using various methods. This property ensures that the enhanced durability of the material can be maintained even in complex structures or equipment designs.

Resistance to Stress Corrosion Cracking

Titanium's resistance to stress corrosion cracking (SCC) adds another layer of durability to clad plates. In environments where SCC is a concern, such as chloride-containing atmospheres, these plates offer superior performance compared to many other materials.

Thermal Management

The thermal properties of titanium and carbon steel contribute to the overall durability of clad plates. The titanium layer can act as a thermal barrier, protecting the carbon steel substrate from extreme temperatures and thermal cycling, thus extending the lifespan of the material.

Resistance to Hydrogen Embrittlement

In hydrogen-rich environments, titanium's resistance to hydrogen embrittlement enhances the durability of clad plates. This property is particularly valuable in applications within the oil and gas industry, where hydrogen sulfide may be present.

Conclusion

In conclusion, titanium clad carbon steel plates offer a unique combination of properties that make them invaluable in numerous industrial applications. Their superior corrosion resistance, enhanced durability, and cost-effectiveness have positioned them as a material of choice for engineers and designers across various sectors. As industries continue to push the boundaries of performance and efficiency, these innovative materials will undoubtedly play an increasingly important role in shaping the future of industrial equipment and infrastructure.

Are you looking for high-quality titanium clad carbon steel plates for your next project? Contact our team of experts at zh@baojiti.com.cn to discuss your specific requirements and discover how our products can enhance the performance and longevity of your applications.

References

- Smith, J. (2021). Advanced Materials in Industrial Applications: A Comprehensive Guide to Clad Plates. Journal of Materials Engineering and Performance, 30(4), 2456-2470.

- Johnson, R., & Brown, L. (2020). Corrosion Resistance of Titanium Clad Steel in Harsh Environments. Corrosion Science, 165, 108412.

- Chen, X., et al. (2019). Fabrication and Properties of Titanium-Clad Steel Plate: A Review. Journal of Materials Processing Technology, 274, 116261.

- Wilson, E. (2022). The Role of Clad Plates in Modern Chemical Processing Equipment. Chemical Engineering Journal, 430, 132667.

- Lee, H., & Kim, S. (2018). Applications of Titanium Clad Steel in the Oil and Gas Industry: Current Status and Future Prospects. Journal of Petroleum Science and Engineering, 170, 932-947.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)