Why Is Copper Clad Plate Essential for High-Performance Electrical Systems?

2025-01-03 09:28:38

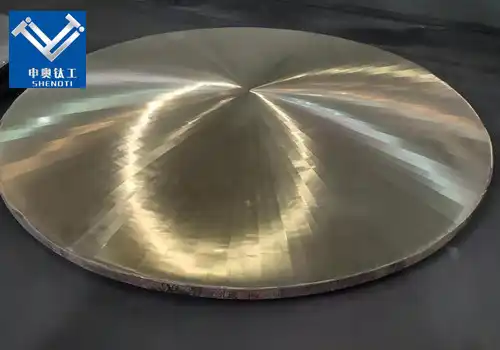

High-performance electrical systems demand materials that can handle high currents, withstand significant heat, and maintain signal integrity. Copper-clad plates, a composite material consisting of a copper layer bonded to a substrate, excel in meeting these demands.

What are the Advantages of Using Copper Clad Plate in High-Frequency Applications?

High-frequency applications, such as in 5G infrastructure and high-speed data transmission, necessitate materials with low resistance and excellent conductivity. Copper, with its superior electrical conductivity, is the ideal choice. However, simply using a solid copper plate can be impractical due to weight, cost, and mechanical limitations. Copper-clad plates offer a solution: the copper layer provides the necessary conductivity, while the substrate material provides structural support and potentially other desirable properties like thermal management or cost reduction.

The substrate material also plays a crucial role in managing the skin effect. At high frequencies, the current tends to concentrate near the surface of a conductor (the skin effect). A copper-clad plate can be designed with a copper layer thickness that optimally interacts with the skin depth for the specific frequency, ensuring minimal signal loss and efficient power transmission. Different substrate materials—like aluminum or fiberglass—can further enhance specific performance aspects, such as thermal dissipation or mechanical strength.

How Does Copper Clad Plate Improve Thermal Management in Power Electronics?

Power electronics generate substantial heat, which can negatively impact their performance and longevity. Efficient thermal management is crucial to prevent overheating and component failure. Copper-clad plates contribute significantly to this by providing a highly conductive pathway for heat dissipation. The copper layer rapidly conducts heat away from the heat-generating components, while the substrate can be designed to facilitate heat transfer to a cooling system, such as a heatsink. This efficient heat dissipation helps maintain optimal operating temperatures, enhancing the reliability and lifespan of the electronic system. The substrate material can be chosen to optimize thermal conductivity, further improving this critical function.

What are the Different Types of Copper Clad Plates and Their Applications?

Copper-clad plates are available in a variety of configurations, each tailored to specific applications. Key factors influencing the choice of a copper-clad plate include:

Copper thickness: This determines the conductivity and current-carrying capacity of the plate. Thicker copper layers offer better conductivity but increase cost and weight.

Substrate material: This affects the mechanical properties, thermal conductivity, and cost of the plate. Common substrate materials include aluminum, fiberglass, and various polymers.

Plate dimensions and shape: These are customized according to the specific requirements of the application.

Surface finish: The surface finish of the copper layer can influence the solderability and overall performance of the plate.

Different applications may require specific combinations of these factors. For example:

High-frequency circuits: Might use thinner copper layers on a dielectric substrate to minimize signal loss.

High-power applications: Might employ thicker copper layers on a substrate with high thermal conductivity to manage heat effectively.

Flexible circuits: Could use copper clad on a flexible substrate like polyimide.

This versatility makes copper-clad plates suitable for a broad range of applications, from power electronics to telecommunications.

Beyond the Subtitles: A Deeper Dive into Copper Clad Plate Properties

The effectiveness of copper-clad plates stems from a synergistic combination of properties:

High Electrical Conductivity: Copper's exceptional electrical conductivity minimizes energy loss during power transmission, improving overall system efficiency.

Excellent Thermal Conductivity: Copper efficiently dissipates heat, preventing overheating and prolonging the lifespan of electronic components.

Mechanical Strength & Stability: The substrate material provides necessary mechanical support and stability, ensuring the plate withstands environmental stresses and handling during manufacturing and operation.

Cost-Effectiveness: While copper is expensive, using a copper-clad plate instead of solid copper often offers a cost-effective solution, especially in large-scale applications. The substrate reduces the overall quantity of copper required.

Ease of Fabrication: Copper-clad plates can be easily fabricated into various shapes and sizes, simplifying manufacturing processes and adapting to diverse design requirements.

Solderability: The copper layer possesses excellent soldera

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)

_副本_1734935304964.webp)