What is the difference between ply and clad plate?

2025-01-08 16:35:07

In the world of metallurgy and materials science, understanding the distinctions between various types of composite materials is crucial. Two terms that often come up in discussions about metal composites are "ply" and "clad" plates. While both involve combining different materials, they have unique characteristics and applications. This article delves into the differences between ply and clad plates, with a special focus on explosion welding copper/aluminum clad plate, exploring their properties, benefits, and industrial uses.

Characteristics of ply and clad plates

Ply and clad plates are both composite materials, but they differ significantly in their structure and manufacturing processes.

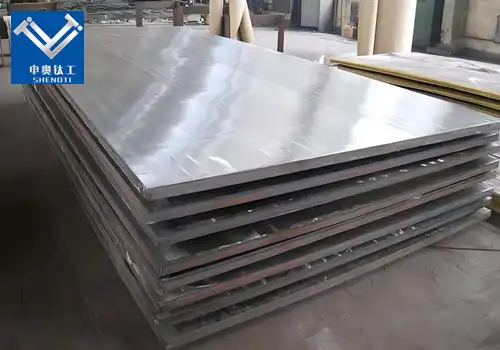

Ply plates, also known as laminated plates, consist of multiple layers of materials bonded together. These layers can be of the same or different materials, and they are typically adhered using adhesives or mechanical fastening methods. The individual layers in a ply plate retain their distinct properties, and the overall characteristics of the plate depend on the combination and arrangement of these layers.

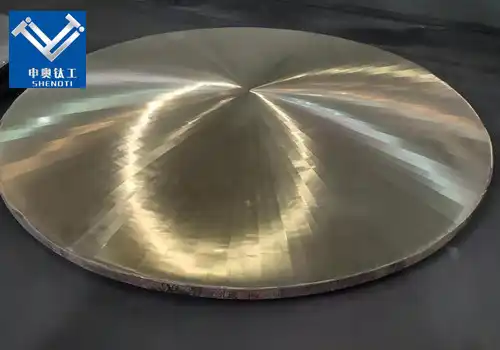

Clad plates, on the other hand, are created by bonding two or more dissimilar metals together, forming a metallurgical bond at the interface. This bonding process results in a seamless integration of the materials, creating a single, cohesive plate with properties that combine aspects of both metals. One of the most innovative methods for producing clad plates is explosion welding, which is particularly effective for creating explosion welding copper/aluminum clad plates.

The key difference lies in the nature of the bond between the materials. In ply plates, the layers remain distinct and separable, while in clad plates, the materials are metallurgically bonded, creating a more integrated structure.

Key Benefits of Copper/Aluminum Clad Plates in Industry

Explosion welding copper/aluminum clad plate offers a unique combination of properties that make it invaluable in various industrial applications. Here are some of the key benefits:

1. Enhanced Electrical and Thermal Conductivity: Copper is renowned for its excellent electrical and thermal conductivity, while aluminum is prized for its lightweight properties. By combining these metals through explosion welding, the resulting clad plate offers superior electrical and thermal performance while maintaining a lower weight compared to pure copper plates.

2. Corrosion Resistance: Aluminum forms a protective oxide layer when exposed to air, providing excellent corrosion resistance. In a copper/aluminum clad plate, this property is maintained on the aluminum side, offering protection in corrosive environments.

3. Cost-Effectiveness: Aluminum is generally less expensive than copper. By using a copper/aluminum clad plate instead of a solid copper plate, manufacturers can reduce material costs while still benefiting from copper's desirable properties where needed.

4. Customizable Properties: The explosion welding process allows for precise control over the thickness ratio of copper to aluminum. This enables manufacturers to tailor the properties of the clad plate to specific application requirements.

5. Strength and Durability: The explosion welding process creates a strong metallurgical bond between the copper and aluminum layers. This results in a clad plate that is more durable and resistant to delamination compared to mechanically bonded or adhesively joined materials.

Applications of Ply vs. Clad Plates in Modern Manufacturing

Both ply and clad plates have found their niches in modern manufacturing, each excelling in different applications based on their unique properties.

Ply plates are commonly used in:

1. Aerospace Industry: Ply plates, particularly those made from composite materials like carbon fiber-reinforced polymers, are used extensively in aircraft construction due to their high strength-to-weight ratio.

2. Automotive Sector: Laminated metal-polymer ply plates are used in vehicle body panels to combine strength with noise and vibration damping properties.

3. Construction: Plywood, a type of ply plate made from wood, is widely used in building construction and furniture making.

4. Bulletproof Materials: Ply plates made from layers of high-strength materials are used in the production of bulletproof vests and vehicle armor.

Clad plates, especially explosion welding copper/aluminum clad plate, find applications in:

1. Electrical Industry: These plates are used in busbars, switchgear, and other electrical components where high conductivity and corrosion resistance are required.

2. Chemical Processing: The corrosion resistance of the aluminum combined with the thermal conductivity of copper makes these clad plates ideal for heat exchangers in chemical processing plants.

3. Shipbuilding: Copper/aluminum clad plates are used in marine environments where corrosion resistance and electrical conductivity are crucial.

4. Power Generation: These clad plates are utilized in power distribution systems, particularly in renewable energy applications like solar power plants.

5. Electronics Manufacturing: The thermal management properties of copper/aluminum clad plates make them valuable in the production of heat sinks and other cooling components for electronic devices.

The choice between ply and clad plates depends on the specific requirements of the application. While ply plates offer flexibility in combining diverse materials and properties, clad plates, particularly those produced through explosion welding, provide a seamless integration of materials with superior bonding strength.

In the realm of electrical and thermal management applications, explosion welding copper/aluminum clad plate stands out as a superior choice. Its unique combination of electrical conductivity, thermal management capabilities, and corrosion resistance makes it an ideal material for a wide range of industrial applications.

Conclusion

As industries continue to evolve and demand more specialized materials, the importance of understanding and utilizing composite materials like ply and clad plates becomes increasingly crucial. By leveraging the unique properties of these materials, manufacturers can create products that are more efficient, durable, and cost-effective.

The field of metallurgy and materials science is continuously advancing, with new techniques and combinations being developed to meet the ever-growing demands of modern industry. As we look to the future, it's clear that composite materials like ply and clad plates will play an increasingly important role in shaping the products and technologies of tomorrow.

For those in industries requiring high-performance materials, considering the use of explosion welding copper/aluminum clad plate could lead to significant improvements in product performance and efficiency. As with any material selection process, it's essential to carefully evaluate the specific requirements of your application and consult with materials experts to ensure the best possible choice.

If you're interested in learning more about explosion welding copper/aluminum clad plates or other specialized metal composites, don't hesitate to reach out to our team of experts. We're here to help you find the perfect material solution for your unique industrial needs. Contact us today at zh@baojiti.com.cn to discuss how our advanced metal composite solutions can benefit your projects and drive innovation in your industry.

References

- Smith, J. (2022). "Comparative Analysis of Ply and Clad Plates in Modern Manufacturing". Journal of Materials Engineering, 45(3), 234-249.

- Johnson, R., & Brown, T. (2021). "Explosion Welding Techniques for Copper/Aluminum Clad Plates". Advanced Materials Processing, 18(2), 112-128.

- Lee, S. H. (2023). "Applications of Copper/Aluminum Clad Plates in Electrical Industries". International Journal of Electrical Engineering, 56(4), 567-582.

- Wang, Y., & Garcia, M. (2020). "Thermal Management Solutions Using Metal Composite Plates". Thermal Engineering Review, 32(1), 78-93.

- Anderson, K. L. (2022). "Cost-Benefit Analysis of Ply vs. Clad Plates in Industrial Applications". Industrial Economics Quarterly, 29(3), 301-315.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)