What Are the Applications of Copper Clad Stainless Steel Plates

2025-01-09 12:04:29

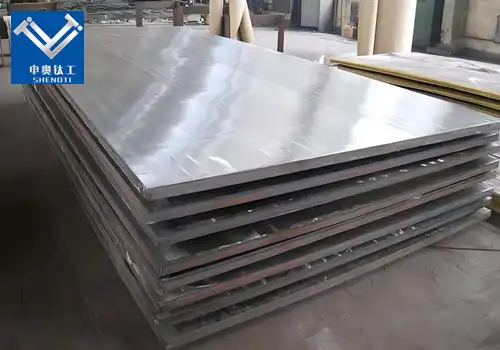

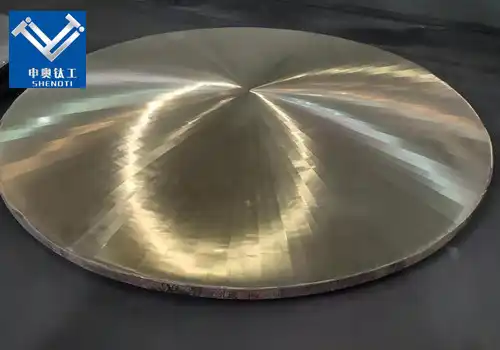

Copper clad stainless steel plates are composite materials that combine the advantageous properties of both copper and stainless steel. This fusion results in a material that offers excellent thermal and electrical conductivity, corrosion resistance, and mechanical strength. Such characteristics make these plates highly desirable in various industries, including electronics, automotive, aerospace, and architecture.

What Are the Applications of Copper Clad Stainless Steel Plates?

Copper clad stainless steel plates are utilized in a wide range of applications due to their unique combination of properties:

Electronics and Electrical Engineering: The excellent electrical conductivity of copper, combined with the durability of stainless steel, makes these plates ideal for components like connectors, circuit breakers, and grounding systems. They are also used in manufacturing parts that require efficient heat dissipation.

Cookware: In the culinary industry, these plates are used to produce high-quality cookware. The copper exterior provides superior heat conduction, while the stainless steel interior offers a non-reactive and durable cooking surface. This combination ensures even cooking and longevity of the cookware.

Architecture: Architects utilize copper clad stainless steel for building facades and roofing. The material offers aesthetic appeal, durability, and resistance to atmospheric corrosion, making it suitable for long-lasting and maintenance-free structures.

Automotive and Aerospace: The high strength-to-weight ratio and corrosion resistance make these plates suitable for manufacturing components in vehicles and aircraft, where durability and performance are critical.

Heat Exchangers: The thermal conductivity of copper combined with the corrosion resistance of stainless steel makes these plates ideal for use in heat exchangers, where efficient heat transfer and durability are essential.

How Are Copper Clad Stainless Steel Plates Manufactured?

The manufacturing process of copper clad stainless steel plates involves bonding a layer of copper onto a stainless steel substrate. This can be achieved through various methods:

Roll Bonding: This process involves pressing and rolling the metals together under high pressure, creating a metallurgical bond. The resulting clad metal exhibits the combined properties of both materials.

Explosive Bonding: A high-energy explosive detonation forces the copper and stainless steel together, resulting in a strong bond. This method is suitable for bonding dissimilar metals with significantly different properties.

Weld Overlay: In this technique, a layer of copper is welded onto the stainless steel surface. This method is often used for applications requiring thick cladding layers.

Each manufacturing method has its advantages and is chosen based on the intended application, required material properties, and cost considerations.

What Are the Benefits of Using Copper Clad Stainless Steel Plates?

The combination of copper and stainless steel in a single plate offers several benefits:

Enhanced Corrosion Resistance: The stainless steel component provides excellent resistance to corrosion, while the copper layer adds an additional barrier against environmental factors.

Improved Thermal and Electrical Conductivity: Copper's superior conductivity makes these plates suitable for applications requiring efficient heat and electrical transfer.

Mechanical Strength: The stainless steel core imparts high mechanical strength, making the plates durable and suitable for structural applications.

Aesthetic Appeal: The copper surface offers a distinctive appearance, which can be desirable in architectural applications.

Cost-Effectiveness: Cladding allows for the use of less copper, reducing costs while still providing the desired properties of both metals.

How Do Copper Clad Stainless Steel Plates Compare to Other Clad Materials?

Copper clad stainless steel plates are one among several types of clad materials, each offering unique properties:

Copper Clad Aluminum: This material is lighter than copper clad stainless steel and offers good electrical conductivity but lacks the same level of mechanical strength and corrosion resistance.

Copper Clad Steel: While similar, copper clad steel generally has lower corrosion resistance compared to stainless steel variants. However, it offers high tensile strength and is often used in grounding applications.

Stainless Steel Clad Aluminum: This combination provides excellent corrosion resistance and is lightweight but does not offer the same level of electrical conductivity as copper-clad materials.

The choice between these materials depends on the specific requirements of the application, including factors like weight, strength, conductivity, and environmental resistance.

About Our Company

Baoji City ShenAo Metal Materials Co., Ltd are a leading manufacturer specializing in the production of high-quality copper clad stainless steel plates. Our state-of-the-art facilities and experienced team ensure that our products meet the highest industry standards. We are committed to providing innovative solutions tailored to the specific needs of our clients across various industries.

Contact Us

For inquiries or to request free samples, please contact us at:

Email: zh@baojiti.com.cn

We look forward to assisting you with your material needs.

References

KLS Clad Metal. "Stainless Steel Clad Plate Applications and Benefits

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)