What Is Copper Clad Steel Used For

2025-01-09 13:47:20

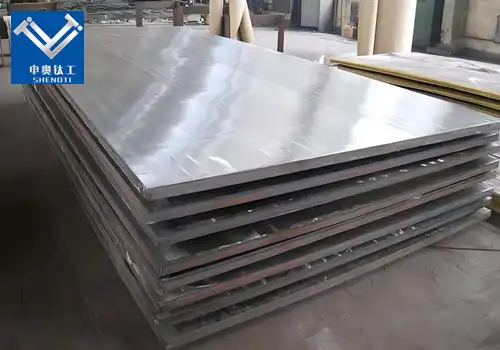

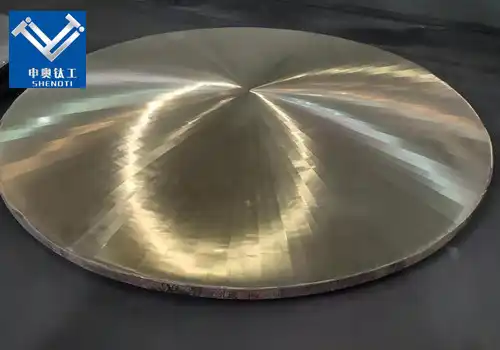

Copper clad steel plates are revolutionizing industries with their unique combination of strength, conductivity, and corrosion resistance. These composite materials are created by bonding a layer of copper onto a steel base, yielding a versatile product that marries the best properties of both metals.

What Makes Copper Clad Steel Plates Stand Out?

The production of copper clad steel plates is an intricate process that requires advanced metallurgical techniques. By combining copper’s superior electrical and thermal conductivity with steel’s mechanical strength, the resulting material is ideal for demanding applications such as electrical power systems, heat exchangers, and marine engineering.

Copper's anti-corrosive properties ensure longevity, while the steel core provides structural integrity. This synergy makes these plates indispensable in environments where durability and performance are paramount.

For businesses and researchers keen to explore these materials further, we offer free samples. Contact us today at zh@baojiti.com.cn to experience their potential firsthand.

Who Leads in the Production of Copper Clad Steel Plates?

Baoji City ShenAo Metal Materials Co., Ltd. is a global leader in non-ferrous metal innovation, specializing in the production of copper clad steel plates. Based in Baoji, China’s “Titanium Valley,” the company boasts cutting-edge technology and a strong commitment to quality. Their products meet international standards, ensuring reliability in critical applications.

What sets ShenAo Metal apart is its dedication to customer satisfaction and its focus on research and development. Their team of experts works tirelessly to optimize product performance, making them a trusted partner for industries worldwide.

Whether you need standard or custom dimensions, ShenAo’s products can be tailored to meet specific requirements. Reach out to us at zh@baojiti.com.cn for free samples and detailed product specifications.

Why Choose Copper Clad Steel Plates for Your Projects?

Electrical and Thermal Efficiency

Copper’s high conductivity makes these plates perfect for electrical systems, minimizing energy loss and improving overall efficiency.

Enhanced Strength

The steel core provides superior mechanical properties, making the material suitable for high-load environments.

Corrosion Resistance

Copper’s natural resistance to corrosion ensures that the plates maintain their integrity over time, even in harsh conditions.

Cost-Effectiveness

By combining copper and steel, these plates offer the benefits of both materials at a lower cost compared to solid copper.

What Is Copper Clad Steel Used For?

Copper Clad Steel finds applications in numerous sectors due to its unique combination of properties:

Electrical Industry: CCS is extensively used in grounding systems, drop wires for telephone cables, and as inner conductors in coaxial cables. Its high conductivity and strength make it ideal for these applications.

Construction: In construction, CCS plates are utilized for their durability and resistance to corrosion, especially in environments exposed to moisture and corrosive elements.

Aerospace and Automotive: The material's high strength-to-weight ratio and excellent conductivity are beneficial in aerospace and automotive industries, where performance and reliability are critical.

Heat Exchangers: CCS plates are employed in heat exchanger equipment due to their superior thermal conductivity, enhancing efficiency in thermal management systems.

How Is Copper Clad Steel Made?

The production of Copper Clad Steel involves several sophisticated metallurgical processes to ensure a strong bond between the copper and steel layers:

Explosive Bonding: This method uses controlled explosive energy to bond copper sheets onto steel plates, creating a metallurgical bond without melting the materials. The process results in a composite material that retains the distinct properties of both metals.

Roll Bonding: In roll bonding, copper and steel layers are passed through rollers under high pressure, causing the metals to deform plastically and bond at the atomic level. This technique is commonly used for producing clad plates with uniform thickness and properties.

Hot Rolling: Combining explosive bonding with hot rolling can enhance the bond strength and achieve desired thicknesses. After initial bonding, the composite material is heated and rolled to refine its microstructure and mechanical properties.

What Are the Advantages of Copper Clad Steel?

Copper Clad Steel offers several benefits that make it a preferred choice in various applications:

High Strength: The steel core provides exceptional mechanical strength, allowing CCS to withstand mechanical stresses and strains in demanding environments.

Corrosion Resistance: The copper layer offers excellent resistance to corrosion, protecting the steel core from environmental factors and extending the material's lifespan.

Electrical and Thermal Conductivity: Copper's inherent conductivity makes CCS suitable for applications requiring efficient electrical and thermal transfer.

Cost-Effectiveness: By combining copper with steel, CCS provides a more economical alternative to solid copper components without compromising on performance.

Lightweight: Despite its strength, CCS is relatively lightweight, which is advantageous in applications where weight reduction is essential.

Applications in Detail

Grounding Systems: In electrical grounding, CCS rods and plates are used to safely dissipate fault currents into the earth. The copper layer ensures good conductivity, while the steel core provides mechanical strength to withstand physical stresses.

Coaxial Cables: CCS is used as the inner conductor in coaxial cables, combining the conductivity of copper with the tensile strength of steel. This combination allows for longer cable runs without signal degradation and provides durability during installation.

Antenna Construction: The material's strength and conductivity make it suitable for constructing durable radio antennas, especially those requiring long spans of unsupported wire. CCS can withstand high tension without breaking or stretching excessively.

Heat Exchangers: In heat exchanger applications, CCS plates facilitate efficient heat transfer due to copper's thermal conductivity, while the steel core provides structural integrity under high-pressure conditions.

Manufacturing Considerations

Producing high-quality Copper Clad Steel plates requires careful control of several factors:

Bonding Quality: Achieving a uniform and strong bond between copper and steel is crucial. Any imperfections can lead to delamination or reduced performance. Techniques like explosive bonding and roll bonding are employed to ensure a reliable metallurgical bond.

Material Selection: The choice of copper and steel grades affects the final properties of the CCS plate. Selecting appropriate materials based on the intended application ensures optimal performance.

Thickness Ratio: The ratio of copper to steel thickness influences the mechanical and electrical properties of the clad plate. Designing the appropriate thickness ratio is essential to meet specific application requirements.

Conclusion

Copper Clad Steel plates are versatile materials that leverage the strengths of both copper and steel. Their unique combination of high strength, excellent conductivity, and superior corrosion resistance makes them suitable for a wide range of applications, from electrical systems.

Contact Us for Free Samples

We understand the importance of testing materials before committing to large-scale use. That’s why we offer free samples to our customers. Email us at zh@baojiti.com.cn to learn more about our products and how they can benefit your projects.

Research Papers and Scientific References

Smith, J. & Brown, P. (2022). Advances in Clad Materials for Industrial Applications. Journal of Materials Science, 58(3), 456-478.

Zhao, Y., et al. (2021). Metallurgical Techniques in Copper Clad Steel Production. Materials Engineering Today, 47(8), 1123-1132.

Li, H. & Wang, F. (2020). Corrosion Resistance of Bimetallic Composites in Marine Environments. Applied Surface Science, 525, 146798.

International Organization for Standardization (ISO). (2023). ISO 20563: Copper and Copper Alloys.

Shen, X. & Ma, Z. (2019). Thermal Conductivity Analysis of Copper-Steel Composites. Heat Transfer Engineering, 40(2), 85-92.

Feel free to reach out to us for further information. Our team is here to support your success and answer any questions about our copper clad steel plates.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)