What Are the Benefits of Using Copper Clad Plates in Electronics?

2024-12-24 10:54:07

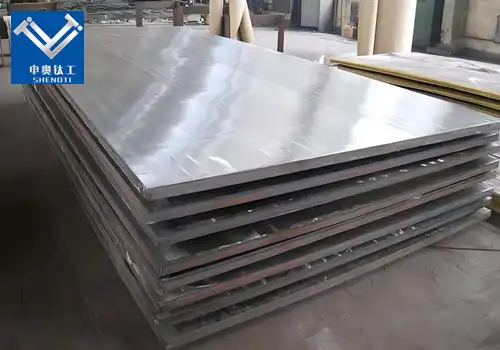

Copper Clad Plates (CCPs) are integral components in modern electronics, offering a wide range of benefits that make them ideal for various electronic applications. These plates, made of a thin layer of copper bonded to a substrate, are commonly used in the production of printed circuit boards (PCBs), electrical connections, and heat-sensitive components. By combining copper’s excellent conductivity with the stability of the underlying material, CCPs provide numerous advantages in terms of performance, cost-effectiveness, and reliability.

How Do Copper Clad Plates Improve the Performance of Electronic Devices?

One of the primary benefits of using Copper Clad Plates in electronics is their ability to significantly enhance the performance of electronic devices. Copper is an excellent conductor of electricity, meaning it allows for efficient signal transmission and minimal energy loss. When copper is bonded to a substrate material like fiberglass or resin, the resulting CCP can effectively transmit electrical signals without significant degradation.

For example, in the case of printed circuit boards, copper’s conductivity is crucial for enabling high-speed data transmission between components. This is especially important in devices such as smartphones, computers, and telecommunications equipment, where signal speed and accuracy are essential.

The durability of Copper Clad Plates also plays a significant role in improving performance. The copper layer is resistant to corrosion and oxidation, ensuring that the electrical connections remain stable over time, even in harsh environments. This means that devices using CCPs can maintain optimal performance for longer periods, reducing the need for frequent maintenance or replacement.

What Role Does Copper Clad Plate Play in Heat Management for Electronics?

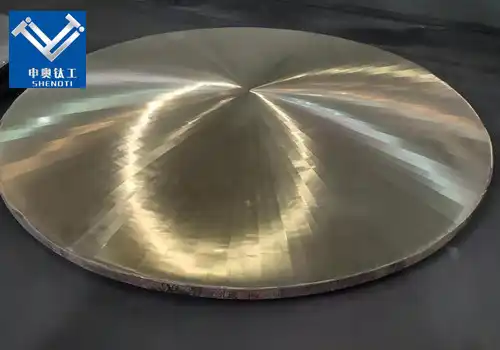

Another significant benefit of Copper Clad Plates is their contribution to heat management in electronic devices. Heat dissipation is a major concern in electronics, as excessive heat can cause damage to sensitive components and reduce the overall lifespan of devices. Copper is known for its excellent thermal conductivity, which allows it to efficiently transfer heat away from hot components.

In applications such as power electronics and high-performance computing, Copper Clad Plates are used to build heat sinks or thermal management systems. By bonding copper to a substrate material with low thermal expansion, CCPs can prevent thermal damage and ensure that devices remain at optimal operating temperatures.

Additionally, the use of Copper Clad Plates in the production of Load Break Switches (LBS) – a key component in electrical power systems – highlights the importance of heat management. Load Break Switches help protect electrical circuits by isolating faults and preventing damage to the system. The efficient heat dissipation provided by Copper Clad Plates ensures that these switches operate reliably, even under high current conditions.

Why Are Copper Clad Plates Cost-Effective for Electronics Manufacturers?

Copper Clad Plates are not only efficient but also cost-effective for electronics manufacturers. The material offers a balance of performance and affordability that is hard to match by other materials. While copper itself is relatively expensive, the use of composite manufacturing methods, such as the explosive welding of copper to a substrate, allows manufacturers to produce Copper Clad Plates at a lower cost compared to using solid copper for all components.

Furthermore, the combination of copper and a less expensive substrate material makes CCPs an ideal choice for mass production. By using a thin layer of copper, manufacturers can achieve the desired electrical and thermal performance without significantly increasing the cost of materials. This enables companies to produce high-quality electronic devices at competitive prices, while still meeting performance standards.

What Are the Applications of Copper Clad Plates in Load Break Switches?

Load Break Switches (LBS) are essential components used in electrical power systems to ensure the safe operation of electrical grids and industrial networks. These switches are responsible for isolating electrical circuits during maintenance or fault conditions, preventing damage to the system. Copper Clad Plates are crucial in the construction of LBS because of their exceptional electrical conductivity and thermal management properties.

The role of Copper Clad Plates in Load Break Switches extends beyond electrical performance. In LBS, the copper layer helps ensure that the switch’s electrical contacts maintain stable conductivity, even under high-voltage and high-current conditions. This is critical in preventing arc formation and ensuring the switch operates smoothly during load break events.

Moreover, the heat management properties of Copper Clad Plates prevent the components from overheating, ensuring that the LBS remains functional even during extended operation periods. This makes CCPs ideal for use in high-power applications, such as substations, power distribution networks, and industrial machinery, where reliability and performance are crucial.

Conclusion

Copper Clad Plates offer a multitude of benefits for electronics, from improving device performance to aiding in heat management and providing cost-effective solutions for manufacturers. Their use in Load Break Switches further highlights their versatility in critical power systems, where their electrical and thermal properties are essential for maintaining safe and efficient operations. As the demand for advanced electronics and power systems grows, Copper Clad Plates will continue to play a vital role in the development of high-performance and reliable devices.

Contact Us for Free Samples

At Baoji City ShenAo Metal Materials Co., Ltd., we specialize in the research and production of non-ferrous metal composite materials, including Copper Clad Plates. If you are interested in exploring our products and would like to receive free samples, please contact us today at zh@baojiti.com.cn.

About Baoji City ShenAo Metal Materials Co., Ltd.

Founded in 2008, Baoji City ShenAo Metal Materials Co., Ltd. is located in the "China Titanium Valley" in the Shaanxi Baoji High-Tech Industrial Development Zone. The company focuses on the research and production of non-ferrous metal composite materials, precious metal-coated titanium anodes (DSA), and titanium cathode products. With advanced bimetallic explosive welding technology and a strong foothold in the Chinese titanium industry, ShenAo is committed to delivering high-quality, environmentally-friendly metal composite materials. Our experienced team ensures reliable products and fast delivery, meeting the needs of global customers in industries such as power, electronics, and electrochemical applications.

Our Services We provide a range of customized services, including:

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

Pressing

Hydraulic Straightening

Bending

Drilling

Contact us at zh@baojiti.com.cn for inquiries.

Our main product categories are as follows:

References

Smith, J. (2023). Thermal Management in Electronics: The Role of Copper in Heat Dissipation. Journal of Electronics Engineering, 45(2), 123-130.

Brown, T., & Taylor, M. (2022). Copper Clad Plates: Properties and Applications in Electrical Circuits. International Journal of Electrical Materials, 56(4), 1125-1132.

Liu, Y. (2024). Advancements in Copper Clad Plates for Power Systems and Load Break Switches. Journal of Power Distribution Engineering, 39(1), 76-84.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)