Why Do Manufacturers Prefer Copper Clad Plates for PCB Fabrication?

2025-01-04 09:30:47

Copper-clad laminates (CCLs) are fundamental to printed circuit board (PCB) fabrication, serving as the foundational material upon which electronic circuits are constructed. Manufacturers favor copper-clad plates due to their exceptional electrical conductivity, thermal management capabilities, mechanical stability, and cost-effectiveness.

Why Do Manufacturers Prefer Copper-Clad Plates for PCB Fabrication?

Copper-clad laminates consist of a substrate material, such as fiberglass-reinforced epoxy resin (FR-4), with a layer of copper foil bonded to one or both sides. This configuration offers several advantages:

Electrical Conductivity: Copper is renowned for its excellent electrical conductivity, second only to silver. This property ensures efficient signal transmission with minimal resistance, which is crucial for the performance of electronic devices.

Thermal Management: Effective heat dissipation is vital to prevent overheating in electronic components. Copper's high thermal conductivity allows it to efficiently dissipate heat, maintaining the reliability and longevity of PCBs.

Mechanical Stability: Copper-clad laminates provide structural integrity to PCBs, offering dimensional stability, bending strength, and resistance to environmental factors. This ensures that the boards can withstand mechanical stresses during manufacturing and operation.

Cost-Effectiveness: While copper is not the cheapest metal, its combination of favorable properties and relative abundance makes copper-clad laminates a cost-effective choice for mass production of PCBs.

What Are the Different Types of Copper-Clad Laminates Used in PCBs?

Manufacturers select copper-clad laminates based on the specific requirements of the electronic application. Common types include:

Metal-Core PCBs (MCPCBs): These laminates incorporate a metal core, often aluminum or copper, to enhance thermal conductivity. They are ideal for high-power applications where heat dissipation is critical.

Flexible Laminates: Made from materials like polyimide, these laminates allow the PCB to bend and flex, suitable for applications requiring flexibility.

How Does the Thickness of Copper in Copper-Clad Laminates Affect PCB Performance?

The thickness of the copper layer in a laminate significantly influences the PCB's electrical and thermal performance:

Standard Thickness: Typically, PCBs use copper thicknesses of 1 oz/ft² (approximately 35 µm). This standard thickness balances conductivity and cost for general applications.

Heavy Copper: For high-current or high-thermal applications, thicker copper layers (up to 3 oz/ft² or more) are used. This reduces impedance and enhances heat dissipation but increases material costs.

Thin Copper: In applications where fine traces are required, thinner copper layers (e.g., 0.5 oz/ft²) are utilized to achieve higher resolution in circuit patterns.

What Are the Common Methods for Manufacturing Copper-Clad Laminates?

The production of copper-clad laminates involves several key steps:

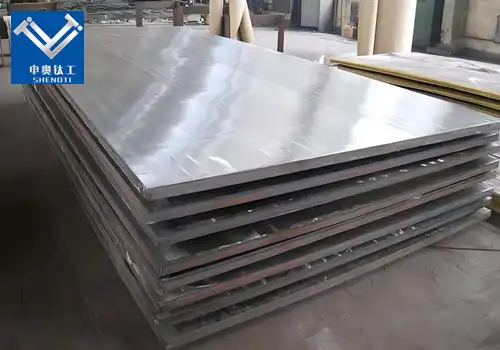

Preparation of Substrate: Materials like fiberglass cloth are impregnated with resin and partially cured to form prepreg sheets.

Lamination: Copper foils are placed on one or both sides of the prepreg sheets, and the assembly is subjected to heat and pressure to bond the layers together.

Curing: The laminated sheets are fully cured to solidify the resin, ensuring mechanical stability.

Finishing: The laminated sheets are trimmed to size, and surface treatments may be applied to enhance solderability and protect against oxidation.

What Are the Advantages and Disadvantages of Using Copper-Clad Laminates in PCBs?

Understanding the pros and cons of copper-clad laminates helps in selecting the appropriate material for specific applications:

Advantages:

High Conductivity: Ensures efficient electrical signal transmission.

Thermal Management: Effective heat dissipation enhances reliability.

Mechanical Strength: Provides structural integrity to the PCB.

Versatility: Suitable for a wide range of applications, from consumer electronics to industrial machinery.

Disadvantages:

Cost: Higher copper content can increase material costs.

Weight: Thicker copper layers add weight, which may be a concern in portable devices.

Processing Challenges: Thick copper layers can be more difficult to etch precisely, potentially affecting the resolution of fine circuit patterns.

Copper-clad laminates are indispensable in PCB fabrication due to their superior electrical and thermal properties, mechanical stability, and adaptability to various applications. Manufacturers' preference for these materials stems from their ability to meet the stringent demands of modern electronic devices, ensuring performance, reliability, and cost-effectiveness.

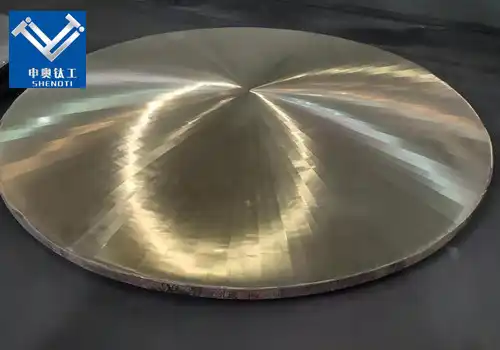

About Baoji City Shenao Metal Materials Co., Ltd.

Baoji City Shenao Metal Materials Co., Ltd. specialize in providing high-quality copper-clad laminates tailored to your specific PCB fabrication needs. With years of experience and a commitment to excellence, we ensure that our products meet the highest industry standards, supporting you in delivering reliable and efficient electronic solutions.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)