What Is the Role of Copper Clad Plates in Power Supply Units

2025-01-03 14:06:35

What Is the Role of Copper Clad Plates in Power Supply Units?

Copper clad plates are pivotal in the functionality and efficiency of modern power supply units (PSUs). These specialized materials, known for their excellent conductivity and durability, are essential components in a variety of applications. In this blog, I will delve into the significance of copper clad plates in PSUs while addressing three high-demand questions about their applications, benefits, and manufacturing processes. By the end, you will understand why these plates are integral to advanced power supply systems.

Why Are Copper Clad Plates Essential for Efficient Power Distribution?

Copper clad plates play a crucial role in ensuring efficient power distribution within PSUs. They serve as the primary conductive pathways, allowing for seamless energy transfer with minimal resistance. The high conductivity of copper reduces energy losses, which is vital for maintaining operational efficiency in electronic devices.

In power supply systems, heat dissipation is a significant concern. Copper’s excellent thermal conductivity ensures that excess heat is effectively managed, preventing overheating and prolonging the lifespan of components. Additionally, the durability of copper clad plates ensures they withstand mechanical stresses and maintain performance under challenging conditions.

For example, in industrial PSUs, copper clad plates are used to connect transformers and capacitors. Their ability to handle high currents without degradation makes them indispensable in high-demand environments. This reliability directly impacts the overall performance and safety of power supply units.

What Are the Advantages of Copper Clad Plates Over Other Materials?

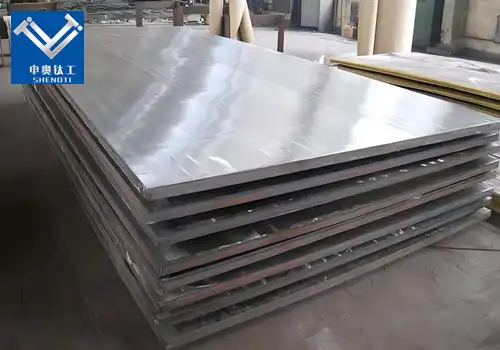

The advantages of copper clad plates over other materials like aluminum or pure copper are rooted in their unique composition. By bonding copper with a substrate material, such as stainless steel or aluminum, manufacturers achieve a balance of cost-efficiency, weight reduction, and enhanced mechanical properties.

Cost Efficiency: While pure copper is expensive, copper clad plates reduce material costs by combining a thin layer of copper with a less costly base metal. This approach retains the conductivity of copper while minimizing expenses.

Weight Reduction: Copper clad plates are lighter than pure copper plates, making them ideal for applications where weight is a concern, such as in aerospace and automotive power systems.

Improved Strength: The substrate material in copper clad plates provides added mechanical strength. This makes them resistant to deformation and ideal for applications requiring robust structural integrity.

Corrosion Resistance: Many copper clad plates feature a corrosion-resistant base, enhancing their durability in harsh environments.

These advantages make copper clad plates the preferred choice for manufacturers aiming to optimize performance without escalating costs. For example, in renewable energy systems, the lightweight and durable nature of copper clad plates support efficient energy transfer while reducing overall system weight.

How Are Copper Clad Plates Manufactured to Ensure Quality?

The manufacturing of copper clad plates involves sophisticated techniques to ensure high-quality output. The most common methods include explosive welding, roll bonding, and adhesive bonding. Each process has unique advantages, tailored to specific industrial requirements.

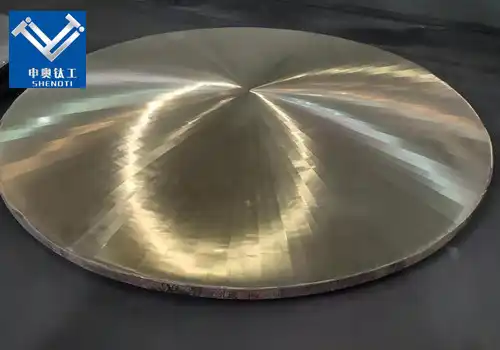

Explosive Welding: This method uses controlled explosive energy to bond copper to a substrate metal. It creates a strong metallurgical bond, ensuring the layers do not separate under mechanical stress. Explosive welding is favored for applications requiring high strength and durability.

Roll Bonding: In this process, copper and the base metal are pressed together under high pressure and heat, creating a uniform bond. Roll bonding is cost-effective and suitable for large-scale production.

Adhesive Bonding: For applications requiring flexibility, adhesive bonding provides a reliable solution. While less durable than metallurgical methods, it is effective for low-stress applications.

Quality assurance is integral to manufacturing. Non-destructive testing methods like ultrasonic testing and X-ray inspection ensure the integrity of the bond and the absence of defects. By adhering to strict quality standards, manufacturers produce copper clad plates that meet the rigorous demands of modern PSUs.

Applications of Copper Clad Plates in Power Supply Units

Copper clad plates are indispensable in various PSU applications, ranging from consumer electronics to industrial machinery. Here are some common uses:

Printed Circuit Boards (PCBs): Copper clad plates are a fundamental component of PCBs, serving as conductive layers for electrical signals.

Transformers: In transformers, copper clad plates facilitate efficient energy transfer and heat dissipation.

Energy Storage Systems: In battery packs and capacitors, these plates enable secure connections and reliable performance.

Renewable Energy Systems: Solar panels and wind turbines rely on copper clad plates for efficient energy distribution and durability in outdoor conditions.

The versatility of copper clad plates underscores their importance across industries. Their ability to combine conductivity, strength, and cost-effectiveness makes them a cornerstone of power supply technology.

Conclusion: Partner with Baoji City ShenAo Metal Materials Co., Ltd.

At Baoji City ShenAo Metal Materials Co., Ltd., we are proud to lead in the production of high-quality copper clad plates. With over 15 years of experience, we have honed our expertise in manufacturing durable and efficient materials that meet global standards. Whether you need solutions for PSUs, PCBs, or renewable energy systems, our team is ready to assist.

Contact us for free samples and let us help you optimize your projects with our superior copper clad plates. Our commitment to innovation and quality ensures that we deliver products that exceed expectations. Join us in advancing the future of power supply technology.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)