What Is the Difference Between Copper Clad Plate and Copper Foil?

2025-01-08 14:24:34

Copper Clad Plates (CCPs) and copper foils are fundamental materials in the electronics industry, particularly in the fabrication of printed circuit boards (PCBs). Understanding their differences is crucial for selecting the appropriate material for specific applications.

What Is the Difference Between Copper Clad Plate and Copper Foil?

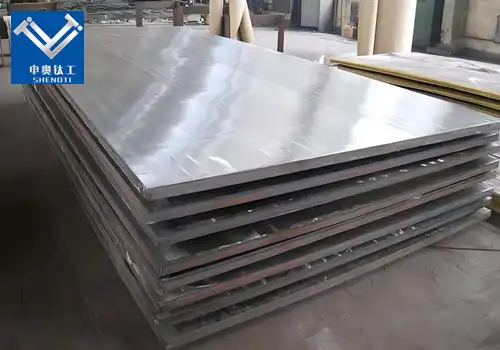

Copper Clad Plates, also known as Copper Clad Laminates (CCLs), are composite materials consisting of a non-conductive substrate, such as fiberglass or resin, bonded with a layer of copper foil on one or both sides. This structure provides mechanical support and electrical conductivity, making CCLs essential in PCB manufacturing.

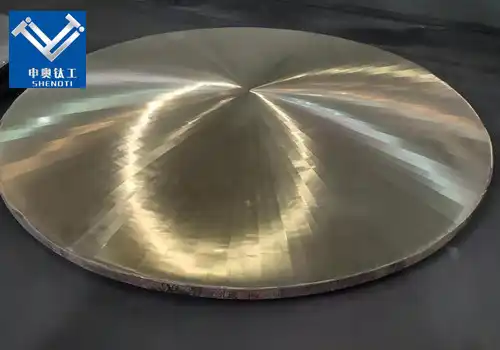

In contrast, copper foil is a thin sheet of pure copper, typically ranging from 18 to 70 micrometers in thickness, with a purity exceeding 99.8%. It serves as the conductive layer in PCBs and is bonded to substrates to form CCLs.

Key Differences:

Composition and Structure:

Copper Clad Plate: Composite material with a substrate and copper foil.

Copper Foil: Single layer of pure copper.

Functionality:

Copper Clad Plate: Provides structural support and electrical pathways in PCBs.

Copper Foil: Acts as the conductive layer, bonded to substrates to create CCLs.

Applications:

Copper Clad Plate: Used directly in PCB fabrication.

Copper Foil: Employed in the production of CCLs and flexible circuits.

Why Is Copper Used in PCBs Instead of Aluminum?

Copper is preferred over aluminum in PCB manufacturing due to its superior electrical conductivity, ductility, and thermal properties. Copper's excellent conductivity ensures efficient signal transmission, while its ductility allows for the creation of intricate circuit patterns without cracking. Additionally, copper's thermal conductivity aids in effective heat dissipation, crucial for maintaining the performance and longevity of electronic components.

What Are the Types of Copper Clad Laminates?

Copper Clad Laminates are categorized based on various factors:

By Insulating Material:

Organic Resin CCLs: Utilize resin-based substrates.

Metal-Based CCLs: Feature metal substrates like aluminum or copper.

Ceramic-Based CCLs: Incorporate ceramic substrates for high-frequency applications.

By Thickness:

Conventional Boards: Thickness ≥ 0.8mm.

Thin Boards: Thickness < 0.8mm, suitable for compact electronic devices.

By Reinforcement Material:

Glass Fiber Cloth CCLs: Offer high strength and insulation.

Paper-Based CCLs: Cost-effective, used in low-end applications.

Composite CCLs: Combine different reinforcement materials for tailored properties.

How Does Copper Thickness Affect PCB Performance?

The thickness of copper in PCBs, often referred to as copper weight, significantly influences the board's electrical and thermal performance:

Signal Integrity: Thicker copper can handle higher current loads, reducing voltage drop and maintaining signal integrity.

Thermal Management: Increased copper thickness enhances heat dissipation, preventing overheating of components.

Mechanical Strength: Thicker copper layers contribute to the PCB's mechanical robustness, improving durability.

However, it's essential to balance copper thickness with design requirements, as excessive thickness can lead to fabrication challenges and increased costs.

Understanding the distinctions between Copper Clad Plates and copper foil is vital for making informed decisions in PCB design and manufacturing. Copper's advantageous properties make it the material of choice in PCBs, and selecting the appropriate type and thickness of copper-clad laminates can significantly impact the performance and reliability of electronic devices.

About Baoji City shenAo Metal Materials Co., Ltd.

Baoji City shenAo Metal Materials Co., Ltd. is a leading provider of high-quality PCB materials and solutions. With a commitment to innovation and excellence, we offer a comprehensive range of products tailored to meet the evolving needs of the electronics industry. Our expertise in copper-clad laminates and related materials ensures that our clients receive top-tier products for their specific applications.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)