What Are the Cost Benefits of Copper Clad Plates in Electronics Manufacturing?

2025-01-04 10:02:38

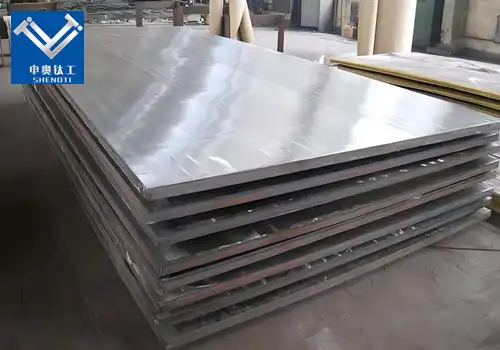

Copper Clad Plates (CCPs), also known as Copper Clad Laminates (CCLs), are fundamental materials in electronics manufacturing, particularly in the production of printed circuit boards (PCBs). They consist of a substrate material, such as glass fiber or wood pulp paper, laminated with copper foil on one or both sides. This structure provides the necessary conductive pathways for electronic components.

What Are the Cost Benefits of Copper Clad Plates in Electronics Manufacturing?

The utilization of CCPs in electronics manufacturing offers several cost advantages:

Material Efficiency: CCPs provide a standardized platform for circuit fabrication, reducing material wastage. The uniformity of copper distribution ensures consistent electrical performance, minimizing the need for additional materials.

Manufacturing Process Optimization: The compatibility of CCPs with automated manufacturing processes enhances production efficiency. Their standardized sizes and properties allow for streamlined fabrication, reducing labor costs and production time.

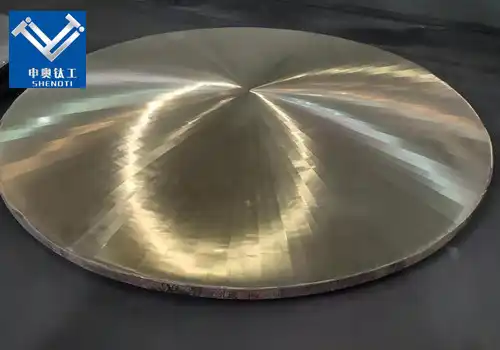

Enhanced Thermal Management: Copper's excellent thermal conductivity aids in effective heat dissipation, reducing the need for additional cooling mechanisms. This property is particularly beneficial in high-power applications, where overheating can compromise device performance and longevity.

Improved Reliability and Longevity: The durability of CCPs contributes to the longevity of electronic devices, reducing failure rates and warranty claims.

How Does the Choice of Copper Clad Plate Material Impact Manufacturing Costs?

The selection of substrate materials in CCPs significantly influences manufacturing costs:

Paper-Based Laminates: These are more cost-effective but may offer lower mechanical strength and thermal resistance, making them suitable for low-end applications.

Metal-Based Laminates: While providing superior thermal management, metal-based laminates are more expensive and are typically reserved for specialized applications.

Manufacturers must balance performance requirements with material costs to achieve cost-effective production.

What Are the Challenges Associated with Using Copper Clad Plates in Electronics Manufacturing?

Despite their advantages, CCPs present certain challenges:

High Initial Costs: The production of CCPs involves significant initial investment, particularly when using high-quality materials like FR-4. This can impact the overall cost structure of electronics manufacturing.

Environmental Concerns: The manufacturing process of CCPs involves chemicals and materials that can pose environmental hazards if not managed properly. Compliance with environmental regulations can add to production costs.

Design Limitations: While CCPs are versatile, they may not be suitable for all circuit designs, especially those requiring flexible substrates. This limitation can necessitate alternative materials, potentially increasing costs.

Copper Clad Plates play a pivotal role in electronics manufacturing, offering a balance between performance and cost. Their material efficiency, compatibility with automated processes, and thermal management properties contribute to cost savings.

About Our Company

We specialize in providing high-quality Copper Clad Plates tailored to the needs of modern electronics manufacturing. Our products are designed to meet industry standards, ensuring reliability and performance. With a commitment to innovation and customer satisfaction, we strive to support manufacturers in achieving cost-effective and efficient production processes.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)