What Are the Advantages of Copper Clad Plates in the Automotive Industry?

2025-01-04 08:35:25

Copper Clad Plates (CCPs) are integral to the automotive industry, offering a blend of mechanical strength, thermal and electrical conductivity, and corrosion resistance.

What Are the Advantages of Copper Clad Plates in the Automotive Industry?

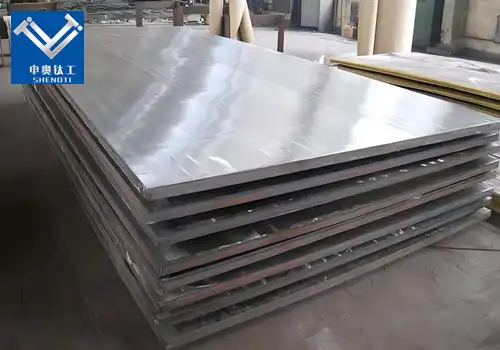

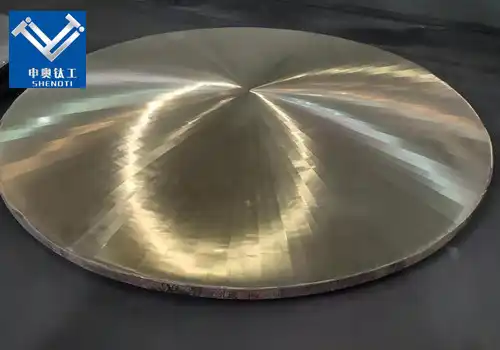

Copper Clad Plates are composite materials that combine the beneficial properties of copper and a base metal, typically steel or aluminum. This combination results in a material that is both versatile and efficient for various automotive applications.

1. Enhanced Thermal Conductivity

Copper is renowned for its excellent thermal conductivity, which is crucial in automotive components that require efficient heat dissipation. When bonded with a base metal, CCPs effectively manage heat in systems such as heat exchangers and radiators, ensuring optimal engine performance and preventing overheating.

2. Superior Electrical Conductivity

The high electrical conductivity of copper makes CCPs ideal for electrical and electronic applications within vehicles. They are commonly used in manufacturing connectors, terminals, and other components where efficient electrical transmission is essential.

3. Corrosion Resistance

The combination of copper and a base metal enhances the corrosion resistance of CCPs. This property is particularly beneficial in automotive environments exposed to various weather conditions and corrosive elements, thereby extending the lifespan of components.

4. Mechanical Strength and Durability

The base metals used in CCPs, such as steel, provide mechanical strength, while the copper layer adds ductility. This combination results in a material that can withstand mechanical stresses and strains, making it suitable for structural components in vehicles.

5. Cost-Effectiveness

By combining copper with less expensive base metals, CCPs offer a cost-effective solution without compromising on performance. This economic advantage makes them attractive for large-scale automotive manufacturing.

6. Lightweight Construction

In applications where aluminum is used as the base metal, CCPs contribute to lightweight vehicle construction. Reducing vehicle weight is essential for improving fuel efficiency and meeting stringent environmental regulations.

7. Versatility in Applications

CCPs are utilized in various automotive components, including heat exchangers, brake systems, and electronic modules. Their versatility stems from the combination of properties that can be tailored to specific application requirements.

How Are Copper Clad Plates Manufactured for Automotive Use?

The manufacturing process of CCPs involves bonding a layer of copper onto a base metal substrate. This can be achieved through several methods:

1. Explosive Welding

This technique uses controlled explosive energy to bond copper and the base metal at high velocities, creating a metallurgical bond without melting the materials. Explosive welding is effective for joining dissimilar metals and produces a strong, uniform bond.

2. Roll Bonding

In roll bonding, copper and the base metal are passed through rollers under high pressure, causing the metals to deform and bond at the atomic level. This method is suitable for producing large sheets of CCPs with consistent thickness and properties.

3. Explosive-Rolling Methods

A combination of explosive welding and rolling, this method initially bonds the metals using explosive energy and then further consolidates the bond through rolling. This hybrid approach enhances the mechanical properties of the CCPs.

What Are the Applications of Copper Clad Plates in Modern Vehicles?

CCPs find applications in various automotive systems due to their unique combination of properties:

1. Heat Exchangers

The excellent thermal conductivity of CCPs makes them ideal for heat exchangers, which are essential for engine cooling and climate control systems. They ensure efficient heat transfer, maintaining optimal operating temperatures.

2. Brake Systems

In brake systems, CCPs are used in components that require both strength and thermal management. Their ability to dissipate heat effectively helps in maintaining braking performance and safety.

3. Electronic Control Units (ECUs)

CCPs are employed in ECUs due to their superior electrical conductivity and reliability. They facilitate efficient signal transmission and power distribution within the vehicle's electronic systems.

4. Sensors and Actuators

The durability and conductivity of CCPs make them suitable for various sensors and actuators that monitor and control vehicle functions, ensuring accurate performance an

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)