What are the advantages of copper-aluminum composite panels

2025-01-08 14:54:03

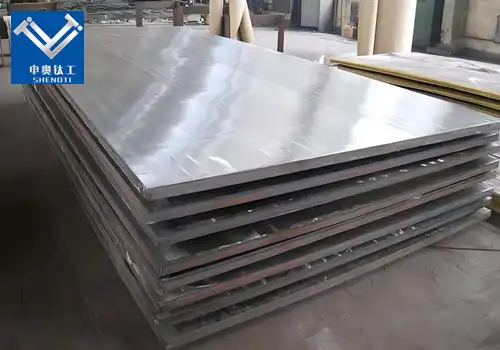

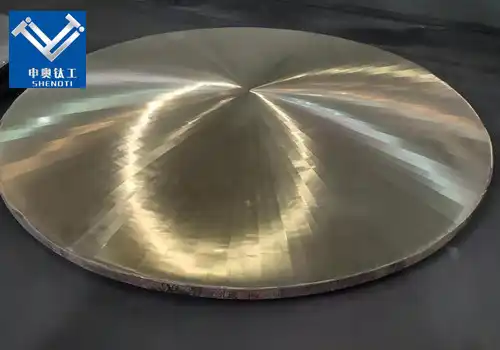

Copper-aluminum clad plates are composite materials that combine the advantageous properties of both copper and aluminum. These plates are extensively used in various industries due to their unique combination of electrical conductivity, thermal performance, and mechanical strength.

What are the advantages of copper-aluminum clad plates?

Copper-aluminum clad plates offer several benefits:

Enhanced Electrical Conductivity: Copper is renowned for its excellent electrical conductivity. When bonded with aluminum, the resulting clad plate maintains high conductivity levels, making it suitable for electrical applications.

Improved Thermal Conductivity: The combination of copper and aluminum results in a material with superior heat dissipation capabilities, essential for applications requiring efficient thermal management.

Lightweight: Aluminum's low density reduces the overall weight of the clad plate compared to pure copper plates, which is advantageous in applications where weight is a critical factor.

Cost-Effective: Aluminum is generally less expensive than copper. By using a copper-aluminum clad plate, manufacturers can reduce material costs without compromising performance.

Corrosion Resistance: The aluminum layer provides a protective barrier against oxidation and corrosion, enhancing the durability of the clad plate.

How are copper-aluminum clad plates manufactured?

The production of copper-aluminum clad plates involves several methods, each with its own advantages:

Explosive Welding: This technique uses controlled explosive energy to bond copper and aluminum plates together. The explosive force causes the metals to collide at high velocity, creating a metallurgical bond without melting the materials. This method is effective for producing strong bonds between dissimilar metals.

Roll Bonding: In this process, copper and aluminum sheets are cleaned and then passed through rollers under high pressure. The pressure causes the metals to deform and bond at the atomic level. Roll bonding is suitable for producing large sheets of clad material with uniform thickness.

Casting and Rolling: This method involves casting molten aluminum onto a solid copper plate, followed by rolling to achieve the desired thickness. The casting process ensures a good bond between the metals, and rolling improves the mechanical properties of the clad plate.

What are the applications of copper-aluminum clad plates?

Due to their unique properties, copper-aluminum clad plates are used in various applications:

Electrical Connectors and Busbars: The high electrical conductivity and lightweight nature of copper-aluminum clad plates make them ideal for use in electrical connectors and busbars, where efficient current flow and weight reduction are essential.

Heat Exchangers: The excellent thermal conductivity of these clad plates makes them suitable for heat exchangers, where efficient heat transfer is crucial.

Cookware: In the cookware industry, copper-aluminum clad materials are used to manufacture high-end pots and pans. The copper layer provides superior heat distribution, while the aluminum core ensures lightweight and cost-effectiveness.

Automotive Industry: These clad plates are used in automotive components that require a combination of strength, conductivity, and corrosion resistance, such as in battery connections for electric vehicles.

Aerospace Industry: The lightweight and high-strength properties of copper-aluminum clad plates make them suitable for aerospace applications, including structural components and thermal management systems.

What are the challenges associated with copper-aluminum clad plates?

While copper-aluminum clad plates offer numerous advantages, there are challenges to consider:

Thermal Expansion Mismatch: Copper and aluminum have different coefficients of thermal expansion. Under temperature fluctuations, this mismatch can lead to internal stresses, potentially affecting the integrity of the bond.

Galvanic Corrosion: When exposed to certain environments, the electrochemical potential difference between copper and aluminum can lead to galvanic corrosion. Proper design and protective measures are necessary to mitigate this issue.

Bonding Quality: Achieving a consistent and defect-free bond between copper and aluminum is challenging. Advanced manufacturing techniques and quality control are essential to ensure the reliability of the clad plates.

How does the thickness ratio of copper to aluminum affect the properties of the clad plate?

The thickness ratio between copper and aluminum layers significantly influences the overall properties of the clad plate:

Electrical Conductivity: A thicker copper layer enhances electrical conductivity, beneficial for applications requiring efficient current flow.

Thermal Conductivity: Both metals contribute to thermal performance, but increasing the copper layer can improve heat dissipation due to copper's superior thermal conductivity.

Mechanical Strength: The aluminum layer contributes to the lightweight nature, while the copper layer adds to the mechanical strength. Adjusting the thickness ratio can balance these properties to meet specific application requirements.

Cost and Weight: A thicker aluminum layer reduces material costs and weight, advantageous in applications where these factors are critical.

What are the environmental considerations in the production and use of copper-aluminum clad plates?

Environmental factors play a crucial role in the lifecycle of copper-aluminum clad plates:

Recycling: Both copper and aluminum are recyclable metals. However, separating them from clad materials can be challenging. Developing efficient recycling methods is essential to minimize environmental impact.

Energy Consumption: Manufacturing processes like explosive welding and roll bonding consume significant energy. Optimizing these processes can reduce the carbon footprint of production.

Resource Availability: The demand for copper and aluminum affects resource extraction and environmental sustainability. Using clad materials can reduce the overall consumption of these metals by combining their properties effectively.

Our main product categories are as follows:

At Baoji City ShenAo Metal Materials Co., Ltd, we specialize in the production of high-quality copper-aluminum composite materials. Our products are designed to meet the diverse needs of modern construction and industrial applications. With a commitment to innovation and quality, we strive to provide materials that offer both functionality and aesthetic appeal.

Are you looking for high-quality copper-aluminum clad plates for your next project? Contact our team of experts at zh@baojiti.com.cn to discuss your specific requirements and discover how our products can enhance the performance and longevity of your applications.

References

"Uses of copper-aluminum composite panels - Application." YG Metal. https://www.ygmetal.com/info/uses-of-copper-aluminum-composite-panels-93465744.html

"What are the advantages and disadvantages of copper clad aluminum wire?" YG Metal. https://www.ygmetal.com/info/what-are-the-advantages-and-disadvantages-of-c-84988875.html

"Benefits Of Using Aluminum Composite Panels." CEI Materials. https://www.ceimaterials.com/news/what-are-the-benefits-of-using-aluminum-composite-panels_ae12.html

"The Facts About Copper-Clad Aluminum (CCA)." Sewell Direct. [https://sewelldirect.com/blogs/learning-center/the-facts-about-copper-clad-aluminum-cca](https://sewelldirect.com/blogs/

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)