How Does Copper Clad Plate Impact the Performance of Heat Exchangers?

2025-01-04 09:14:30

Copper clad plates, which combine the advantageous properties of copper and steel, play a pivotal role in enhancing the performance of heat exchangers. By integrating the thermal conductivity of copper with the strength of steel, these composite materials offer significant benefits in heat exchanger applications.

How Does Copper Clad Plate Impact the Performance of Heat Exchangers?

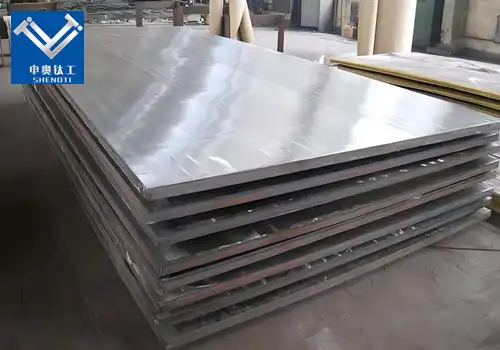

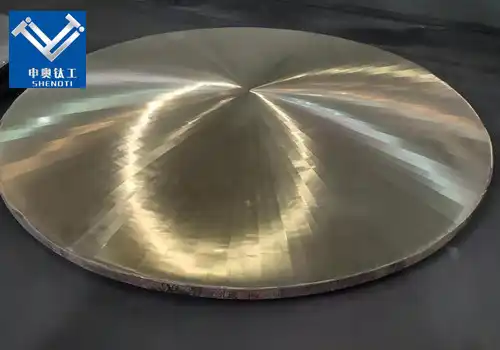

Copper clad plates are engineered by bonding a layer of copper onto a steel substrate, resulting in a material that leverages the high thermal conductivity of copper and the mechanical strength of steel. This combination is particularly beneficial in heat exchangers, where efficient heat transfer and structural integrity are paramount.

The copper layer facilitates rapid heat conduction, enhancing the overall efficiency of the heat exchanger. Simultaneously, the steel substrate provides the necessary durability and resistance to pressure, ensuring the heat exchanger can withstand demanding operational conditions. This synergy between copper and steel results in a heat exchanger that is both efficient and robust.

What Are the Advantages of Using Copper Clad Plates in Heat Exchangers?

The utilization of copper clad plates in heat exchangers offers several notable advantages:

Enhanced Thermal Conductivity: Copper's superior thermal conductivity ensures efficient heat transfer, which is crucial for the performance of heat exchangers.

Corrosion Resistance: The copper layer provides excellent resistance to corrosion, extending the lifespan of the heat exchanger, especially in environments prone to oxidation.

Mechanical Strength: The steel substrate imparts high mechanical strength, allowing the heat exchanger to endure high-pressure conditions without compromising structural integrity.

Cost-Effectiveness: Combining copper and steel in a clad plate can be more economical than using pure copper components, offering a balance between performance and cost.

How Does the Thickness of the Copper Layer Affect Heat Exchanger Performance?

The thickness of the copper layer in a copper clad plate significantly influences the performance of a heat exchanger:

Heat Transfer Efficiency: A thicker copper layer can enhance heat transfer capabilities due to the increased conductive material, improving the exchanger's efficiency.

Corrosion Resistance: Thicker copper layers provide better corrosion resistance, protecting the underlying steel and prolonging the equipment's lifespan.

Material Costs: While a thicker copper layer offers performance benefits, it also increases material costs. Therefore, it's essential to balance performance requirements with budget constraints.

What Are the Applications of Copper Clad Plates Beyond Heat Exchangers?

Beyond heat exchangers, copper clad plates find applications in various industries due to their unique properties:

Electronics Industry: Used in the production of printed circuit boards (PCBs), where the copper layer provides a reliable foundation for circuitry, and the steel base ensures durability.

Automotive Industry: Employed in components that require both conductivity and strength, such as heat exchangers and brake systems.

Aerospace Industry: Utilized in components that must endure extreme conditions, including fuel systems and heat shields.

Construction and Architecture: Applied for both functional and aesthetic purposes, including exterior cladding, roofing, and structural components.

Conclusion

Incorporating copper clad plates into heat exchanger design offers a harmonious blend of thermal efficiency, mechanical strength, and corrosion resistance. By understanding the impact of copper layer thickness and recognizing the material's versatility across various applications, engineers and designers can make informed decisions to optimize heat exchanger performance and extend the lifespan of their equipment.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)