How Does Copper Clad Plate Help in Thermal Management?

2025-01-03 15:14:57

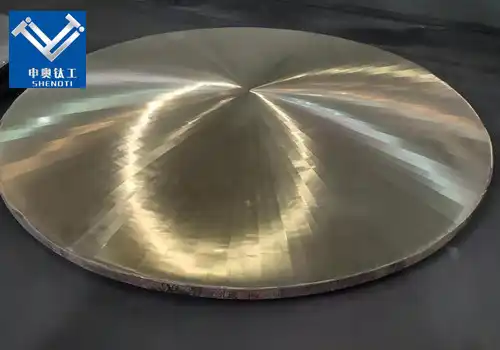

Copper-clad laminates (CCLs) are fundamental materials in printed circuit boards (PCBs), playing a pivotal role in the thermal management of electronic devices. Effective heat dissipation is crucial to maintain the performance and longevity of electronic components.

How Do Copper-Clad Laminates Enhance Heat Dissipation in PCBs?

Copper, known for its excellent thermal conductivity, is integral to CCLs. In PCBs, the copper layers facilitate efficient heat transfer from active components to the surrounding environment. By increasing the thickness of copper layers, the thermal performance of the PCB can be significantly improved. For instance, heavy copper boards, utilizing copper weights of 2 ounces or more, can dissipate more heat without the need for additional technologies.

The use of thermal vias—plated through-holes that connect different copper layers—allows heat to be conducted away from hotspots, distributing it more evenly across the board. This design strategy is particularly effective in multilayer PCBs, where internal layers can serve as heat spreaders.

What Are the Common Thermal Management Challenges in PCB Design?

Despite the advantages of CCLs, several challenges persist in PCB thermal management:

Component Density: High-density component placement can lead to localized heat accumulation, making it difficult for the copper layers alone to dissipate heat effectively.

Material Limitations: While copper has high thermal conductivity, the dielectric materials in CCLs may not, potentially impeding overall heat dissipation.

Design Constraints: Incorporating sufficient thermal vias and optimizing copper thickness must be balanced against factors like signal integrity and manufacturability.

How Can Designers Optimize CCLs for Better Thermal Performance?

To enhance thermal management using CCLs, designers can consider the following strategies:

Selecting Appropriate Materials: Choosing CCLs with high thermal conductivity dielectrics can complement the copper layers, facilitating better heat dissipation.

Implementing Thermal Vias: Strategically placing thermal vias beneath heat-generating components can create efficient heat pathways to other layers or external heatsinks.

Optimizing Copper Thickness: Determining the optimal copper thickness is crucial; while thicker copper can improve thermal performance, it may also introduce challenges in etching precision and increased costs.

Thermal Simulation: Utilizing thermal analysis tools during the design phase can help predict heat distribution and identify potential hotspots, allowing for proactive design adjustments.

In conclusion, copper-clad laminates are essential in the thermal management of PCBs, offering pathways for heat dissipation through their conductive layers. By understanding and addressing the associated challenges, and by implementing strategic design practices, engineers can optimize the thermal performance of electronic devices, ensuring reliability and efficiency.

About Our Company

Baoji City Shenao Metal Materials Co., Ltd.specializes in providing high-quality copper-clad laminates tailored for advanced PCB applications. With a commitment to innovation and excellence, we offer materials that meet the stringent thermal management requirements of today's electronic designs. Our expert team is dedicated to supporting your projects with customized solutions and technical expertise. Contact us to learn more about how our products can enhance your PCB designs.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)