How Can Copper Clad Plate Improve the Durability of Electronic Devices?

2025-01-07 08:57:38

Copper Clad Plates (CCPs), also known as Copper Clad Laminates (CCLs), are fundamental components in the manufacturing of printed circuit boards (PCBs), which serve as the backbone of electronic devices. By providing a stable platform for electronic circuits, CCPs significantly enhance the durability and performance of electronic devices.

What Are the Benefits of Using Copper Clad Plates in Electronics?

Copper Clad Plates consist of a non-conductive substrate material, such as fiberglass-reinforced epoxy resin (FR4), onto which a layer of copper foil is laminated on one or both sides. This construction offers several advantages:

Excellent Electrical Conductivity: The copper layer provides superior electrical pathways, ensuring efficient signal transmission and reducing energy loss.

Mechanical Strength: The substrate material imparts high mechanical strength, allowing the laminate to withstand stress and impact during manufacturing and operation.

Thermal Management: Copper's high thermal conductivity aids in dissipating heat generated by electronic components, maintaining optimal operating temperatures and preventing overheating.

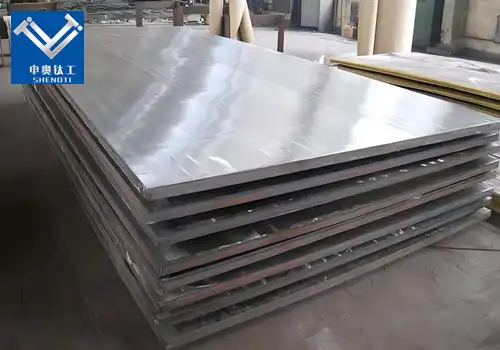

盛奥板材

Corrosion Resistance: The copper layer is resistant to corrosion and oxidation, ensuring that electrical connections remain stable over time, even in harsh environments.

How Does Copper Clad Plate Enhance the Reliability of PCBs?

The integration of Copper Clad Plates in PCBs contributes to the overall reliability of electronic devices in several ways:

Signal Integrity: The uniform copper layer ensures consistent signal transmission, minimizing the risk of signal degradation or loss, which is crucial for high-speed and high-frequency applications.

Structural Integrity: The combination of a robust substrate and copper layer provides mechanical stability, reducing the likelihood of physical damage during assembly and use.

Thermal Stability: CCPs can withstand high temperatures during soldering processes and operation, preventing delamination and ensuring long-term performance.

What Role Does Copper Clad Plate Play in Heat Management for Electronics?

Effective heat management is vital for the longevity and reliability of electronic devices. Copper Clad Plates contribute significantly in this regard:

Heat Dissipation: Copper's excellent thermal conductivity allows it to efficiently dissipate heat away from critical components, preventing overheating and potential failure.

Thermal Conductivity: The copper layer facilitates uniform heat distribution across the PCB, reducing hotspots and enhancing overall device performance.

Thermal Expansion: The materials used in CCPs are engineered to have compatible thermal expansion coefficients, minimizing stress and potential damage due to temperature fluctuations.

How Does the Choice of Substrate Material in Copper Clad Plates Affect Device Performance?

The substrate material in a Copper Clad Plate plays a crucial role in determining the electrical, thermal, and mechanical properties of the PCB:

Electrical Insulation: The substrate provides necessary electrical insulation between different circuit layers, preventing short circuits and ensuring signal integrity.

Mechanical Support: It offers structural support for the copper traces and mounted components, maintaining the physical integrity of the PCB.

Thermal Management: Certain substrate materials, like FR4, have specific thermal properties that influence the PCB's ability to manage heat.

What Are the Different Types of Copper Clad Laminates and Their Applications?

Copper Clad Laminates come in various types, each suited for specific applications:

FR4 Laminates: Made from fiberglass-reinforced epoxy resin, these are widely used in consumer electronics due to their excellent balance of electrical insulation, mechanical strength, and cost-effectiveness.

Flexible Laminates: Utilizing flexible substrates like polyimide, these laminates are used in applications requiring bending and flexing, such as wearable electronics and flexible displays.

High-Frequency Laminates: Designed for high-speed and high-frequency applications, these laminates use specialized materials to minimize signal loss and electromagnetic interference.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)