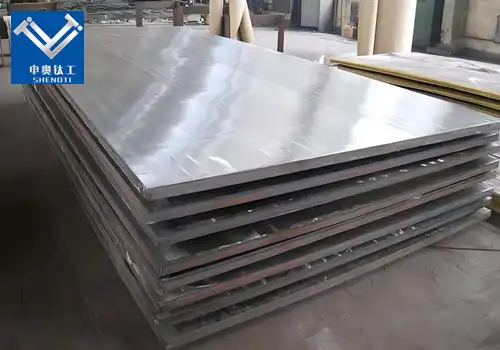

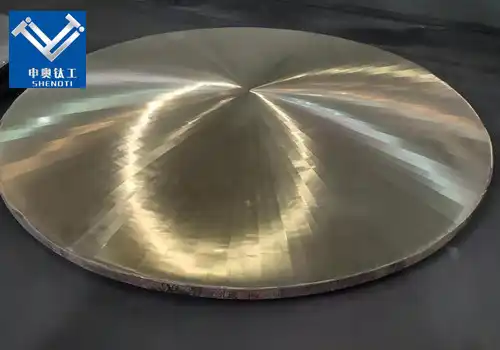

Copper Alloy Steel Clad Plates Manufacturing Processes

2025-01-10 16:51:45

Copper alloy steel clad plates are composite materials that combine the advantageous properties of both copper and steel. These plates consist of a carbon or low-alloy steel base with a layer of copper or copper-base alloy integrally bonded to one or both sides. This combination results in a material that offers the mechanical strength of steel alongside the electrical conductivity and corrosion resistance of copper.

Manufacturing Processes

The production of copper-steel clad plates typically involves methods such as explosion bonding or roll bonding. Explosion bonding uses controlled explosive detonations to fuse the metals together, creating a strong metallurgical bond. Roll bonding, on the other hand, involves pressing the metals together under high pressure and temperature to achieve the desired bond. These processes ensure a continuous and integral bond between the copper and steel layers, resulting in a durable and reliable material.

Applications

Copper-steel clad plates are utilized in various industries due to their unique combination of properties:

Power Generation Equipment: In power plants, especially in condenser tubes and heat exchangers, these clad plates enhance heat transfer efficiency. The copper layer ensures effective thermal conductivity, while the steel base provides structural support, making them ideal for steam condensers and high-temperature environments.

Marine Engineering: The excellent corrosion resistance of the copper layer makes these plates suitable for seawater piping systems and shipbuilding. They are commonly used in constructing hulls, piping systems, and heat exchangers exposed to saltwater.

Electrochemical Equipment: In industries like electrolysis and electroplating, the superior electrical conductivity and corrosion resistance of copper-steel clad plates are invaluable. They are often employed in the construction of anodes, cathodes, and electrolytic cells.

Electrical Busbars and Conductors: These clad plates are used in electrical busbars, transformers, and power distribution systems. The copper layer ensures efficient electrical transmission, while the steel provides mechanical strength, making them suitable for handling high electrical currents in industrial applications.

Technical Specifications

According to ASTM B432-19, the standard specification for copper and copper alloy clad steel plates, these materials are generally intended for pressure vessel use but may also be used in other structural applications where corrosion resistance or conductivity is crucial. The specification outlines requirements for dimensions, mechanical properties, and chemical composition to ensure the quality and performance of the clad plates.

Advantages

The combination of copper and steel in clad plates offers several benefits:

Cost-Effectiveness: Utilizing a steel base with a copper cladding reduces material costs compared to solid copper components while still providing the desired properties.

Enhanced Properties: The clad plates exhibit improved mechanical strength, corrosion resistance, and electrical and thermal conductivity, making them suitable for demanding applications.

Versatility: These materials can be tailored to specific requirements by adjusting the thickness ratios of the copper and steel layers, allowing for customization based on application needs.

Contact Us

For more information or to request free samples of our copper alloy steel clad plates, please contact us at zh@baojiti.com.cn.

Our main product categories are as follows:

Research and References

ASTM International. (2019). B432-19 Standard Specification for Copper and Copper Alloy Clad Steel Plate. Retrieved from https://www.astm.org/b0432-19.html

FUGO Tech. (n.d.). Applications of Copper-Steel Clad Plate. Retrieved from https://www.fugo-tech.com/-material-info-applications-of-copper-steel-clad-plate/

Mashayekhi, M., Dehghani, F., Torabian, N., & Salimi, M. (2015). An Experimental and Numerical Study of Ductile Fracture of Copper/Stainless Steel Clad Sheet in Deep Drawing Process. IJST, Transactions of Mechanical Engineering, 39(M1), 77-87. Retrieved from https://www.academia.edu/124462025/An_Experimental_and_Numerical_Study_of_Ductile_Fracture_of_Copper_Stainless_Steel_Clad_Sheet_in_Deep_Drawing_Process

Wikipedia. (n.d.). Copper-clad steel. Retrieved from https://en.wikipedia.org/wiki/Copper-clad_steel

For further inquiries or to discuss your specific requirements, feel free to reach out to us at zh@baojiti.com.cn.

We look forward to assisting you with your copper alloy steel clad plate needs.

Contact us for free samples and experience the quality of our products firsthand.

YOU MAY LIKE

(1)_副本_1734936765500.webp)

(1)_副本_1734935519643.webp)