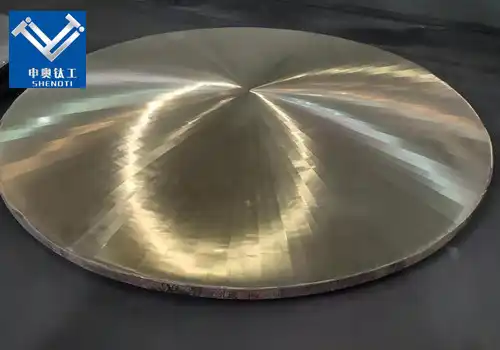

Introduction To Copper Clad Stainless Steel Plate

Copper Clad Stainless Steel Plate is a highly functional material that combines the best qualities of stainless steel and copper. A seamless bond between layers is ensured by the use of cutting-edge explosive welding technology in the creation of this inventive product. Its special composition combines the corrosion resistance and durability of stainless steel with the superior thermal and electrical conductivity of the copper layer. Industries that require high performance and dependability in challenging conditions are the perfect fit for it.

Technical Specifications

| Property | Details |

|---|---|

| Base Material | Stainless Steel (304/316/430, etc.) |

| Cladding Material | Copper (C11000, C10200, etc.) |

| Thickness Ratio | Customizable (e.g., 3mm stainless steel, 1mm copper) |

| Bonding Strength | ≥ 14 MPa |

| Thermal Conductivity | Copper Layer: 385 W/m·K; Stainless Layer: 15 W/m·K |

| Electrical Conductivity | Copper Layer: ≥ 85% IACS |

| Working Temperature | -200°C to +600°C |

| Standards | ASTM B898, GB/T 8165, or as specified |

|

|

|

|

|

|

Product Features

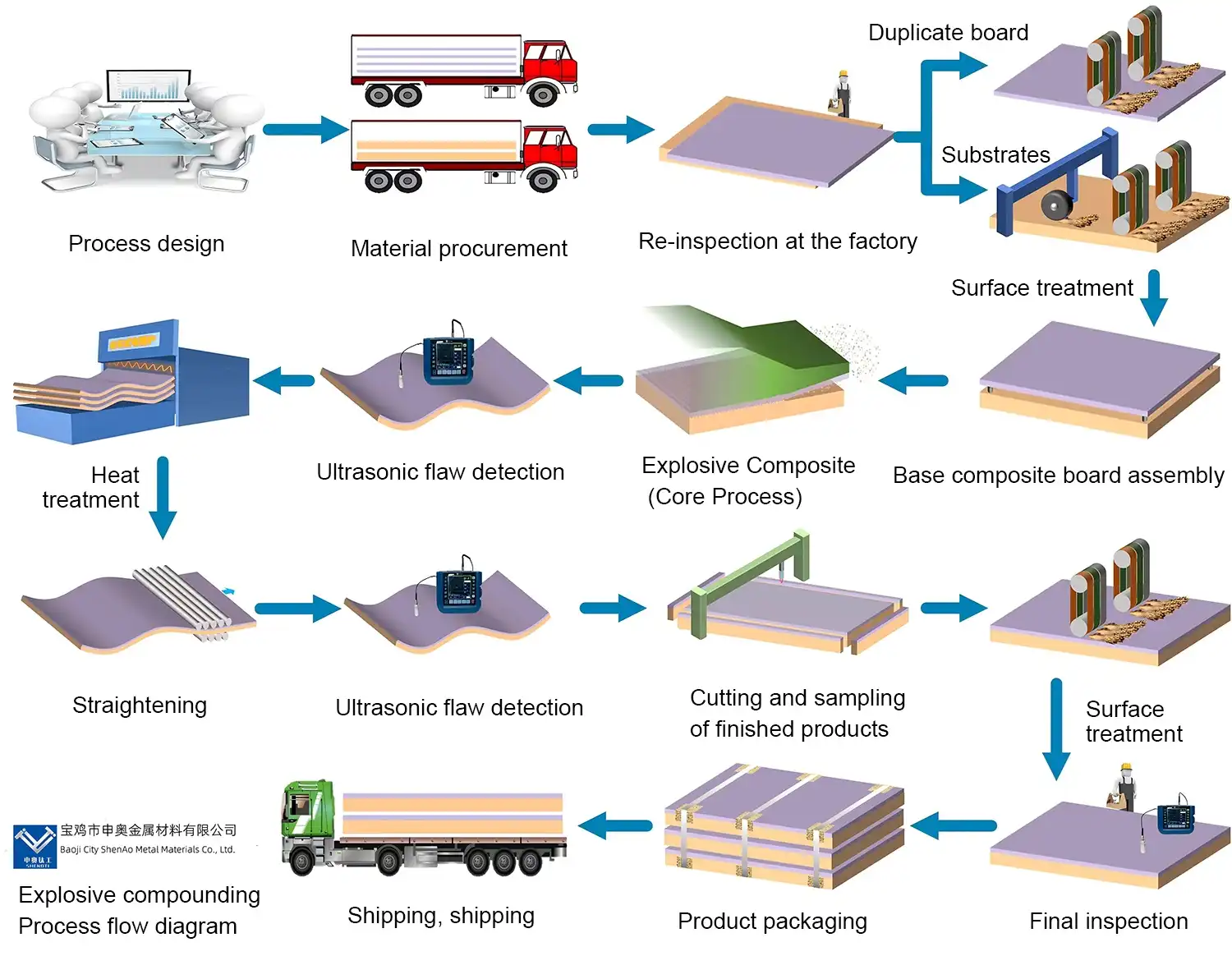

- Outstanding Bonding Strength: Employing advanced explosive welding technology, our copper-clad stainless steel plate ensures a highly uniform and robust bond, offering exceptional durability for various industrial applications.

- Superior Corrosion Resistance: The combination of copper and stainless steel provides outstanding protection against oxidation, acids, and harsh marine environments, making it highly resistant to corrosion and enhancing its longevity.

- Enhanced Thermal and Electrical Conductivity: This material excels in both thermal and electrical conductivity, facilitating efficient energy transfer in applications requiring high-performance heat or electrical management.

- Customizable Specifications: Tailored to meet specific requirements, the plate can be customized in terms of thickness, size, and material properties, offering versatile solutions for diverse industries.

- Cost-Effective Solution: By seamlessly integrating two metals into a single plate, it optimizes cost-efficiency without sacrificing performance, delivering significant savings on material costs.

Applications

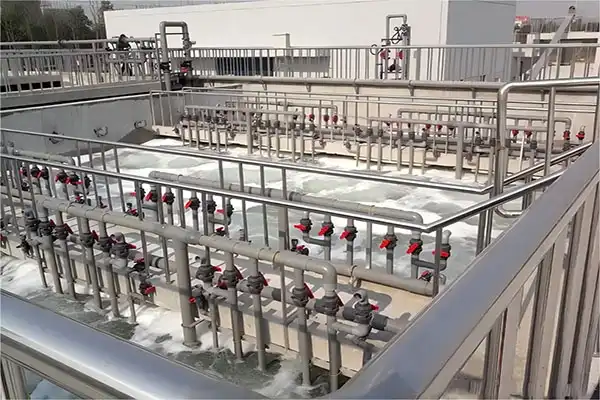

- Chemical and Energy: Copper Clad Stainless Steel Plates are critical in the manufacturing of heat exchangers, reactors, and pressure vessels. Their exceptional ability to withstand both high temperatures and aggressive chemicals makes them indispensable in the energy and chemical industries, ensuring long-term operational efficiency and safety.

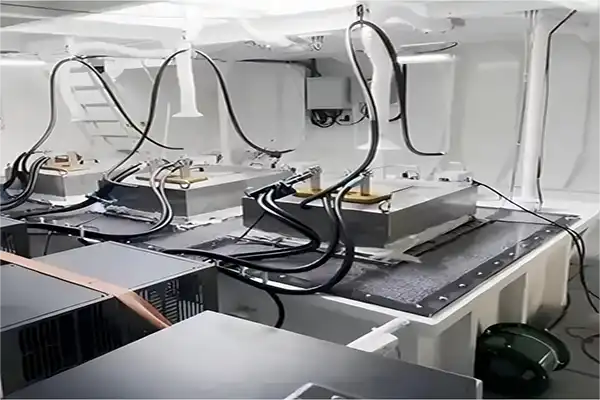

- Electrical and Power Equipment: These plates are widely used in the production of conductive busbars, terminal plates, and grounding systems. Their combination of excellent electrical conductivity and mechanical strength enhances the reliability and durability of power distribution and electrical systems across various sectors.

- Marine Industry: Due to their superior corrosion resistance, copper-clad stainless steel plates are ideal for marine applications, including the construction of anti-corrosion components for ships, offshore platforms, and other marine infrastructure. These plates offer long-lasting protection against the harsh conditions of saltwater environments.

- Construction: Copper-clad stainless steel plates are increasingly utilized in architectural and construction projects for their aesthetic appeal and functional performance. These plates are commonly found in decorative panels, cladding, and other architectural elements, providing both visual elegance and structural resilience.

- Transportation: The combination of lightweight properties and exceptional corrosion resistance makes copper-clad stainless steel plates highly suitable for various transportation applications. These plates are used in automotive, aerospace, and other transport industries to improve fuel efficiency, reduce maintenance costs, and enhance the lifespan of components.

|

|

|

|

|

|

|

Product production process

Why Choose Us

- Research and Innovation: With a skilled R&D team, we continuously explore new materials and processes to ensure our products meet the highest industry standards.

- Proven Expertise: With over 17 years of experience, Baoji ShenAo Metal Materials Co., Ltd. has established itself as a trusted name in the metal-clad industry.

- Unmatched Quality: Our comprehensive quality control system ensures every product meets stringent performance requirements.

- Tailored Solutions: We offer customized services to cater to diverse industry applications, ensuring each client gets the perfect solution for their needs.

- Timely Delivery and Reliable Support: With efficient production and logistics, we deliver on time while offering ongoing technical and after-sales support.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

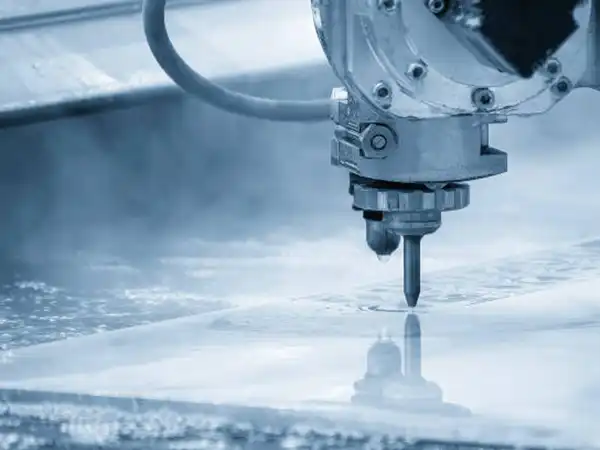

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

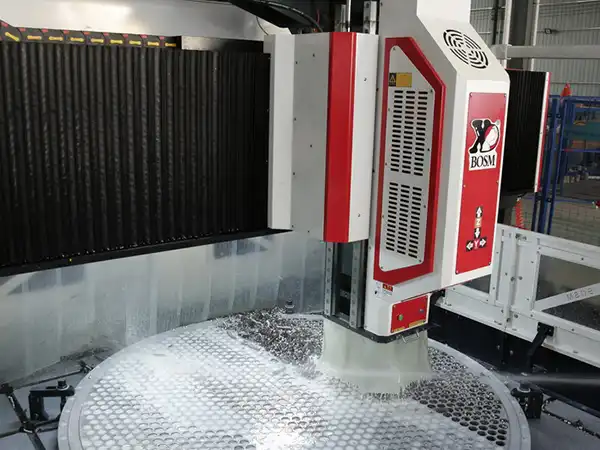

Polishing

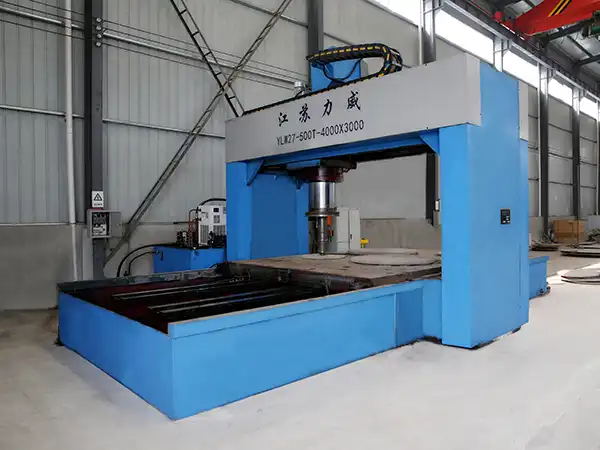

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

Q1: How is the copper layer bonded to the Copper Clad Stainless Steel Plate?

A1: The layers are bonded using explosive welding, a process that creates a high-strength metallurgical bond.

Q2: Can the product be customized for my specific needs?

A2: Absolutely! We offer customizable thickness, dimensions, and material combinations.

Q3: What certifications does the product meet?

A3: Our products comply with ASTM, GB/T standards, and additional certifications as required by clients.

Contact Us

For more information or to discuss your specific requirements:

- Company: Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City.

- Contact: Wang Shujuan

- Phone: 18729731603

- Email: zh@baojiti.com.cn

Let us help you find the ideal solution for your metal-clad needs!

YOU MAY LIKE

_副本_1734935795250.webp)

_副本_1734935851207.webp)

(1)_副本_1734935519643.webp)

_副本_1734935304964.webp)