Introduction to Anodic Titanium Oxide

Anodic titanium oxide is a highly durable and corrosion-resistant coating that forms on the surface of titanium and its alloys when subjected to an electrolytic process. This anodizing technique enhances the natural properties of titanium, creating a protective layer that not only improves the material's resistance to corrosion but also gives it enhanced aesthetic appeal. With widespread applications in various industries such as chemical processing, electronics, and marine, anodic titanium oxide plays a crucial role in ensuring the longevity and reliability of titanium components.

The anodizing process involves applying an electrical current to titanium in an electrolyte bath, which results in the formation of a thick oxide layer. This process can be controlled to vary the thickness of the oxide layer, allowing customization for specific applications. In addition to providing corrosion protection, anodic titanium oxide coatings can also exhibit unique colors, adding to the aesthetic appeal of the material, which is widely utilized in various sectors.

Technical Specifications

Below are the key technical specifications for anodic titanium oxide:

| Property | Value |

|---|---|

| Oxide Thickness Range | 1 µm to 100 µm |

| Hardness | 350–500 HV |

| Corrosion Resistance | Excellent in seawater and acidic environments |

| Color Range | Light to dark hues, depending on the thickness of the oxide layer |

| Porosity | Low porosity for enhanced durability |

| Dielectric Strength | Up to 10 kV/mm |

| Temperature Resistance | Up to 400°C |

| Adhesion Strength | Excellent, typically above 20 N/mm² |

| Electrical Conductivity | Low (insulating property) |

These specifications make anodic titanium oxide a highly versatile material for a wide range of industrial applications where resistance to environmental factors and durability are paramount.

Key Features of Anodic Titanium Oxide

-

Corrosion Resistance: One of the standout features of anodic titanium oxide is its superior corrosion resistance. This makes it ideal for use in harsh environments, such as seawater desalination systems, wastewater treatment plants, and chemical processing units, where metals are prone to corrosion.

-

Durability: The oxide layer formed during anodizing is incredibly hard and resistant to wear. This enhanced hardness makes it perfect for use in high-stress environments where materials are subjected to friction or high mechanical loads.

-

Aesthetic Appeal: The anodizing process allows for the creation of different color finishes on titanium surfaces, which can be tailored to specific design requirements. This property makes anodic titanium oxide a preferred choice for applications where both performance and aesthetics are important.

-

Electrical Insulation: Anodic titanium oxide is an excellent electrical insulator, making it ideal for use in electronic applications, where the prevention of electrical conductivity is necessary.

-

Biocompatibility: Titanium is known for its biocompatibility, and anodizing further enhances this property. This makes anodic titanium oxide an excellent material for medical devices, implants, and other healthcare applications.

Applications of Anodic Titanium Oxide

Anodic titanium oxide finds applications in a wide variety of industries, owing to its excellent properties. Some key applications include:

-

Chemical and Energy Industry: Used for components that need to resist harsh chemicals and high temperatures, such as electrolytic cells and corrosion-resistant parts in reactors.

-

Environmental Protection Industry: Widely used for anodes in wastewater treatment systems and desalination plants, where resistance to aggressive chemical environments is required.

-

Electronics Industry: Anodized titanium is used in various electronic components that need to be electrically insulating yet durable, such as capacitors and circuit boards.

-

Marine Industry: Titanium, with anodic oxide coating, is ideal for marine environments where resistance to seawater corrosion is critical.

-

Medical and Pharmaceutical: Due to its biocompatibility, anodic titanium oxide is used in surgical implants and other medical devices.

-

Transportation: Used in the manufacturing of components that require both high strength and resistance to environmental conditions.

Why Choose Baoji City ShenAo Metal Materials Co., Ltd. for Anodic Titanium Oxide Products

At Baoji City ShenAo Metal Materials Co., Ltd., we specialize in the production of high-quality anodic titanium oxide and other advanced metal composite materials. Here's why you should choose us as your supplier:

-

Research and Innovation: Our experienced R&D team continuously explores new applications and processes, ensuring our products meet the evolving needs of industries. We are committed to innovation and quality improvement.

-

Excellent Reputation: With over 17 years in the industry, we have established a strong reputation for delivering top-notch products that meet the highest standards of quality and performance.

-

Striving for Excellence: Our long-standing commitment to quality has earned us the trust of customers globally. We employ strict production processes and comprehensive quality control systems to ensure the reliability of every product we offer.

-

Customized Product Services: We provide customized solutions tailored to meet your specific needs. Whether you require specialized sizes, thicknesses, or coatings, we have the capability to deliver.

-

Timely Delivery & After-Sales Service: We value our customers and are committed to providing timely delivery and excellent after-sales support. We ensure our customers experience a hassle-free process from order to installation.

-

OEM Services: We offer OEM services to help you design and manufacture custom products based on your technical specifications, ensuring a perfect fit for your requirements.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

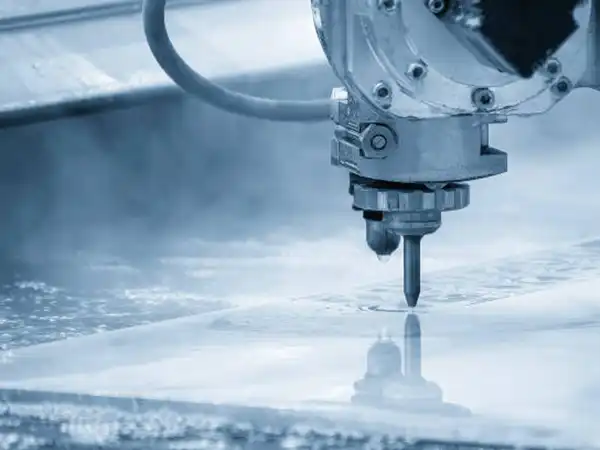

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

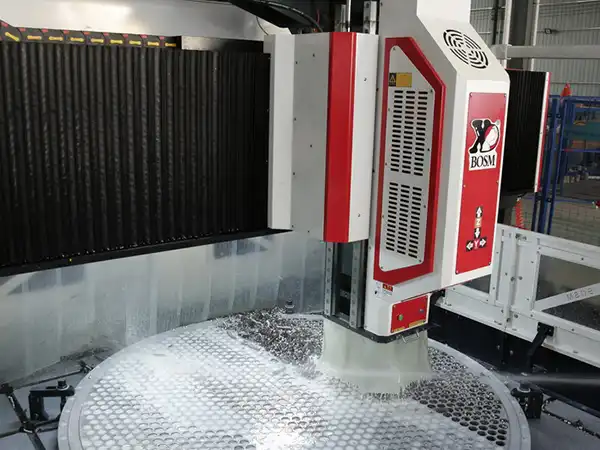

Press

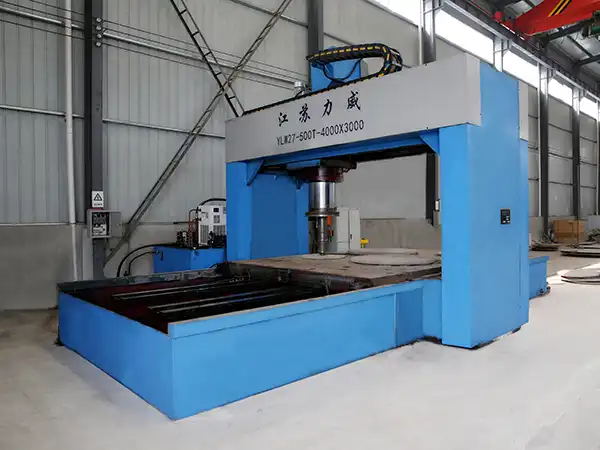

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

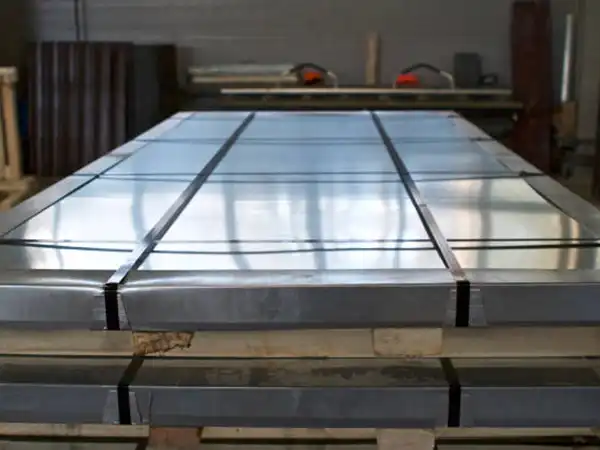

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

FAQs

-

What is anodic titanium oxide used for?

- Anodic titanium oxide is used in various industries, including chemical processing, wastewater treatment, electronics, marine, and medical sectors. It offers excellent corrosion resistance, durability, and electrical insulation.

-

How is anodic titanium oxide applied?

- The anodizing process involves immersing titanium in an electrolyte bath and applying electrical current to form a thick oxide layer on its surface. The thickness and color of the oxide layer can be controlled.

-

Can anodic titanium oxide be used in seawater applications?

- Yes, anodic titanium oxide provides exceptional resistance to seawater corrosion, making it ideal for marine applications such as seawater desalination and shipbuilding.

-

Is anodic titanium oxide biocompatible?

- Yes, titanium is naturally biocompatible, and anodizing further enhances this property, making it suitable for use in medical implants and devices.

Contact Us

For more information or to request a quote, contact us today:

- Company Name: Baoji City ShenAo Metal Materials Co., Ltd.

- Address: Wenquan Village Industrial Park, High-Tech Zone, Baoji City

- Contact Person: Wang Shujuan

- Phone: 18729731603

- Fax: +86-917-3380538

- Email: zh@baojiti.com.cn

_1735350952097.webp)

(1)_1734580705587.webp)