High strength and durability for demanding applications.

Excellent thermal and electrical conductivity performance.

Customizable sizes to suit specific project needs.

Reliable bonding ensures long-lasting structural integrity.

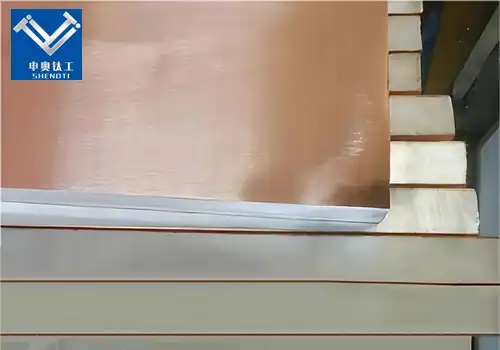

Aluminum-titanium-steel Clad Plate Introduction

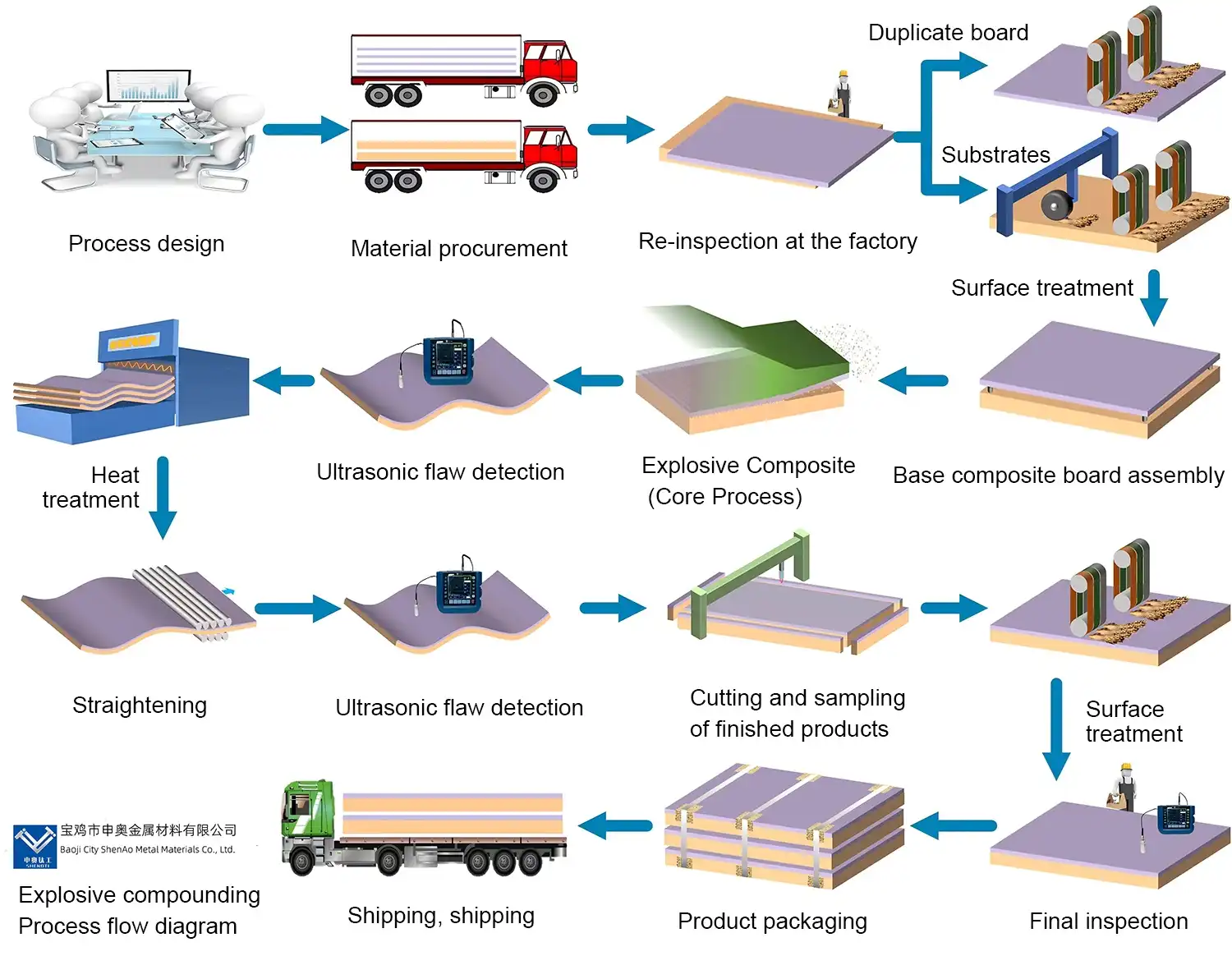

The Aluminum-Titanium-Steel Clad Plate is an advanced composite material combining the unique properties of aluminum, titanium, and steel through an innovative explosive welding technique. This product offers exceptional corrosion resistance, mechanical strength, and thermal conductivity, making it ideal for demanding applications in industries such as chemical processing, marine engineering, and energy production. Its multilayer structure ensures durability and adaptability, delivering high performance in extreme conditions.

Technical Specifications

| Parameter | Value |

|---|---|

| Material Composition | Aluminum (Grade 3003), Titanium (Grade TA1), Steel (Grade Q345B) |

| Thickness (Total) | Customized: 3mm - 20mm |

| Aluminum Layer Thickness | 1mm - 5mm |

| Titanium Layer Thickness | 0.5mm - 3mm |

| Steel Layer Thickness | 1.5mm - 12mm |

| Welding Method | Explosive Welding |

| Bonding Strength | ≥ 200 MPa |

| Corrosion Resistance | Excellent against seawater and chemicals |

| Operating Temperature | -50°C to 600°C |

| Size | Max Width: 2000mm, Max Length: 6000mm |

| Standards Compliance | ASTM B898, GB/T 8165-2020 |

|

|

|

Key Features

- Corrosion Resistance: The titanium layer provides superior resistance to seawater, acids, and alkalis.

- High Bonding Strength: Ensures durability and reliability under high-pressure and high-temperature conditions.

- Lightweight and Strong: Aluminum reduces weight while steel provides mechanical strength, striking the perfect balance.

- Customizable: Tailored to specific thickness, size, and application requirements.

- Environmentally Friendly: Energy-saving and recyclable, contributing to sustainability goals.

- Wide Temperature Range: Performs reliably in both cryogenic and high-temperature environments.

Aluminum-titanium-steel clad plate Applications

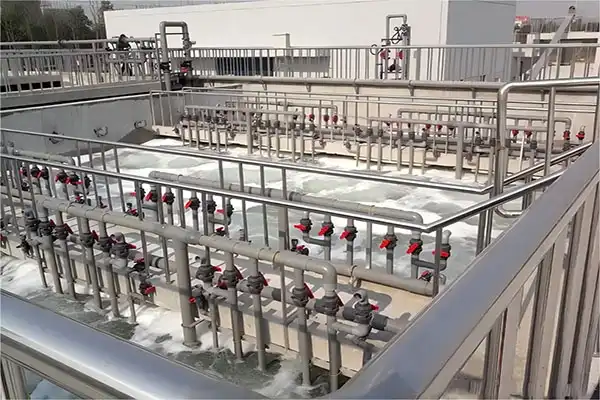

- Chemical Processing: Aluminum-titanium-steel clad plate is ideal for reactors, heat exchangers, and storage tanks requiring chemical resistance.

- Marine Engineering: Used in shipbuilding and offshore structures for its resistance to seawater corrosion.

- Energy Industry: Critical for power plants, especially in seawater cooling systems and pipelines.

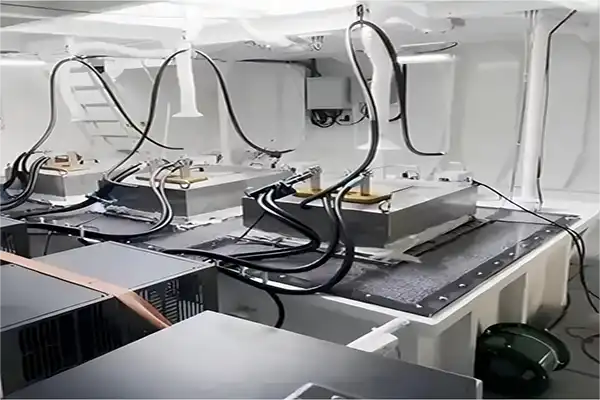

- Electronics: Suitable for heat dissipation in electronic components and assemblies.

- Environmental Protection: Integral in wastewater treatment systems and desalination plants.

|

|

|

|

|

|

|

Product production process

Why Choose Us?

1. Research and Innovation

At Baoji City ShenAo Metal Materials Co., Ltd., we prioritize continuous improvement and innovation. With a dedicated R&D team, we explore new processes and applications, ensuring our products meet evolving industry demands.

2. Excellent Reputation

With over 17 years of experience, we have built a legacy of trust and quality. Our aluminum-titanium-steel clad plates are renowned for their performance and reliability.

3. Striving for Excellence

Our stringent production standards and comprehensive quality management system guarantee that every product exceeds expectations, whether for small-scale projects or large-scale industrial needs.

4. Customized Solutions

We offer tailored services to match your unique specifications, ensuring the perfect solution for your project.

5. Timely Delivery and Support

With efficient production processes and logistics, we ensure prompt delivery and comprehensive after-sales support, keeping your operations seamless.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

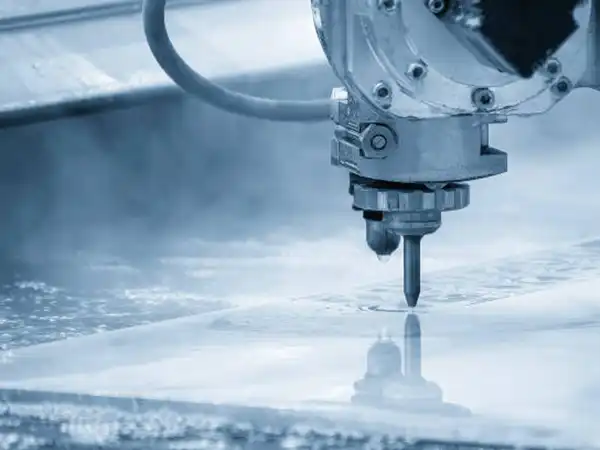

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

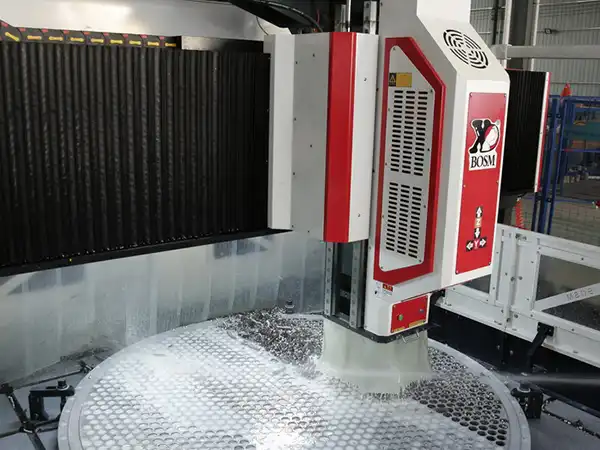

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

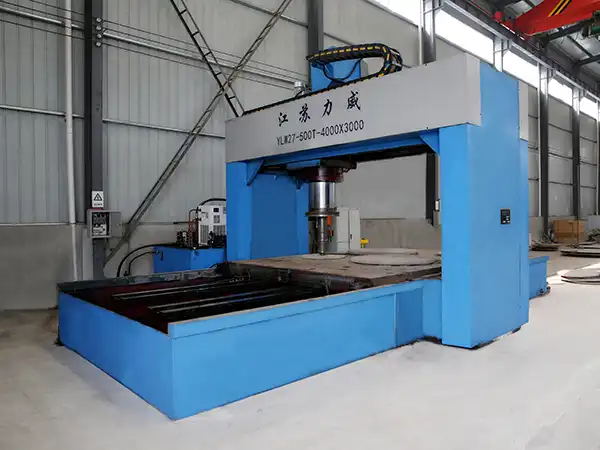

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

OEM Services

We provide OEM manufacturing services, including custom designs, specific dimensions, and tailored production runs. Whether you need prototype development or full-scale production, our team is ready to deliver.

Frequently Asked Questions (FAQs)

Q1: What is the maximum size available for the clad plate?

A: Our aluminum-titanium-steel clad plates can be customized up to 2000mm in width and 6000mm in length.

Q2: How does explosive welding ensure durability?

A: Explosive welding creates a metallurgical bond between layers, ensuring high bonding strength and reliability under extreme conditions.

Q3: Can the product be used in cryogenic applications?

A: Yes, the product performs reliably in temperatures as low as -50°C.

Q4: Do you provide technical support?

A: Absolutely! Our team offers guidance on material selection, application advice, and post-purchase support.

Contact Details

For more information or to request a quote about aluminum-titanium-steel clad plate, please reach out to us:

Name: Baoji City ShenAo Metal Materials Co., Ltd

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact Person: Wang Shujuan

Phone: +86-18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

Conclusion

The Aluminum-Titanium-Steel Clad Plate is a cutting-edge solution for industries demanding high-performance materials. Whether you're in chemical processing, marine engineering, or energy production, this product offers unparalleled benefits in strength, durability, and environmental sustainability. Contact Baoji City ShenAo Metal Materials Co., Ltd. today to learn how our solutions can elevate your operations!

YOU MAY LIKE

_1735023839895.webp)

_1735354912738.webp)

_1735350267851.webp)

_1735892978630.webp)

_1735347173319.webp)