High strength and durability for demanding applications.

Excellent thermal and electrical conductivity performance.

Customizable sizes to suit specific project needs.

Reliable bonding ensures long-lasting structural integrity.

Stainless Steel Composite Plate for Pressure Vessels

Product Introduction

The Stainless Steel Composite Plate for Pressure Vessels is an advanced material designed for use in demanding environments such as chemical processing, energy generation, and high-pressure systems. This product combines the durability and strength of stainless steel with the corrosion resistance and thermal conductivity of composite materials, making it an ideal choice for pressure vessels that require long-lasting performance under extreme conditions.

The composite plates are manufactured using cutting-edge technology, ensuring superior bonding between the metal layers, which enhances the overall structural integrity. These plates are customizable to meet specific requirements for pressure vessels, providing reliable and cost-effective solutions for a wide range of industries.

Technical Specifications

| Feature | Specification |

|---|---|

| Material Type | Stainless Steel / Composite Metal Layer |

| Thickness | 3mm to 50mm |

| Dimensions | Customizable (Length: Up to 4000mm; Width: Up to 1500mm) |

| Density | 7.85 g/cm³ |

| Yield Strength | ≥ 250 MPa |

| Tensile Strength | ≥ 550 MPa |

| Corrosion Resistance | Excellent in Acidic and Alkaline Environments |

| Operating Temperature | -20°C to 600°C |

| Welding Compatibility | Compatible with most welding methods |

| Surface Finish | Smooth, Polished, or Textured |

| Coating Options | Can be coated with various materials such as nickel or titanium for enhanced corrosion resistance |

| Applications | Pressure Vessels, Chemical Reactors, Energy Plants, Marine Engineering |

|

|

|

|

Product Features (Key Features)

- Corrosion Resistance: The stainless steel composite plate is designed to withstand highly corrosive environments, making it ideal for industries such as chemicals, energy, and water treatment.

- High Strength and Durability: The material's combination of stainless steel and composite metals provides enhanced strength and durability, making it capable of withstanding high-pressure conditions.

- Thermal Conductivity: The composite construction ensures efficient thermal management, which is essential for high-temperature applications in power plants and chemical reactors.

- Customizable Solutions: Plates can be tailored to meet specific thickness, dimensions, and coating requirements, ensuring versatility for different pressure vessel applications.

- Weldability: The material is compatible with a wide range of welding processes, offering flexibility during fabrication.

Applications

Stainless Steel Composite Plates are ideal for a variety of applications, including but not limited to:

- Pressure Vessels: Essential for maintaining the integrity of pressure vessels in industries like oil and gas, chemical manufacturing, and power generation.

- Chemical Reactors: Used in the construction of reactors that handle aggressive chemicals and high temperatures.

- Marine Engineering: Ideal for shipbuilding and offshore platforms due to its superior resistance to seawater corrosion.

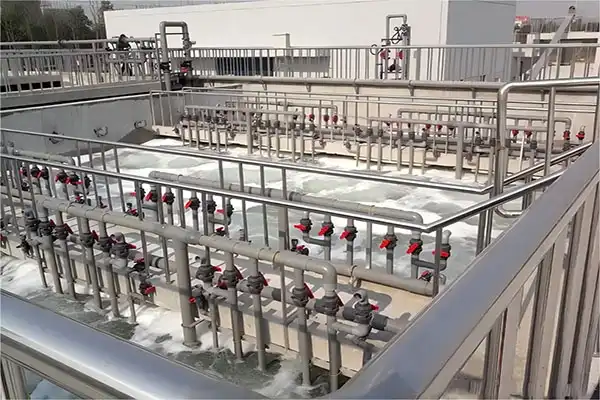

- Water Treatment: Used in the construction of electrolytic cells and wastewater treatment systems due to its corrosion resistance and conductivity.

- Energy Production: Suitable for energy plants, especially in high-temperature and high-pressure environments, ensuring reliable operation.

|

|

|

|

|

|

|

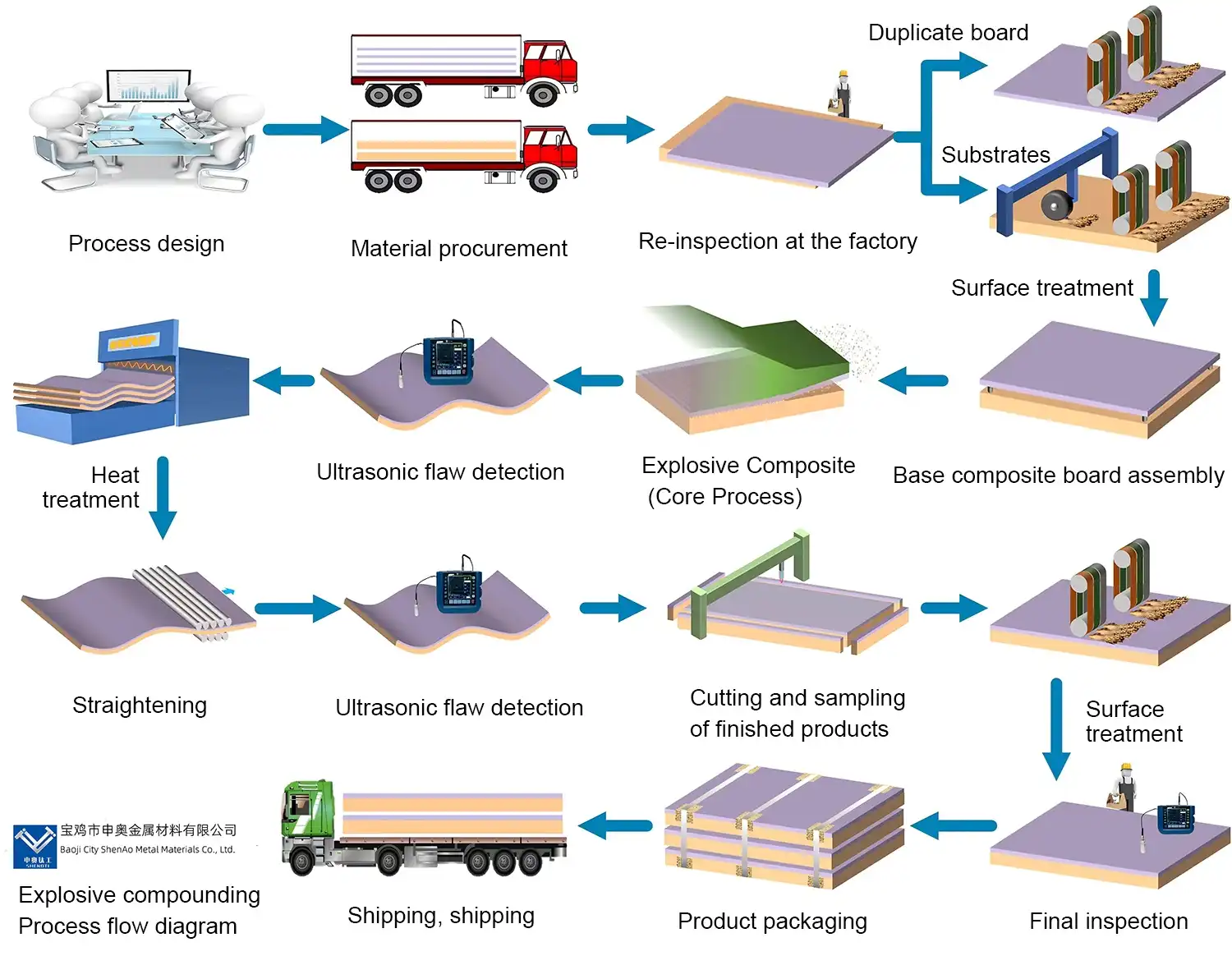

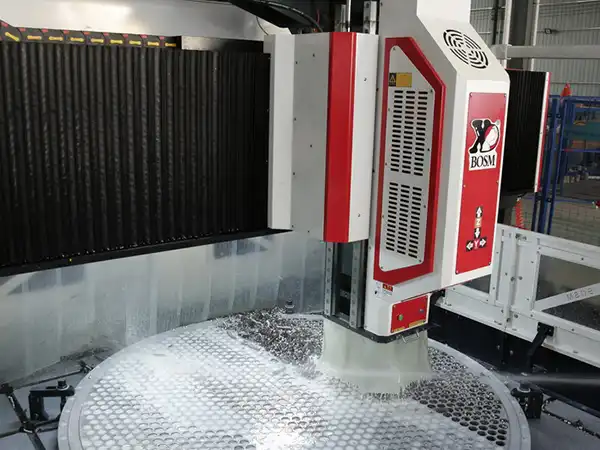

Product production process

Why Choose Us?

-

Research and Innovation Baoji City ShenAo Metal Materials Co., Ltd. boasts a skilled R&D team dedicated to continuous innovation. Our team works closely with clients to explore new processes and applications, ensuring the best solutions for their needs. We are committed to advancing product performance and meeting emerging industry standards.

-

Excellent Reputation With over 17 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. has built a reputation for high-quality products and excellent customer service. Our brand is synonymous with trust and reliability in the metal materials industry.

-

Striving for Excellence Our strict quality control processes ensure that every product meets international standards. From small batch testing to large-scale production, we consistently deliver high-quality products on time, ensuring that all customer requirements are met.

-

Customized Product Services We offer tailored solutions for non-ferrous metal composite materials, including specific metal combinations and customized thicknesses, providing our clients with the precise materials they need for their applications.

-

Timely Delivery, Worry-Free After-Sales Service Our customer-centric approach means we prioritize fast delivery and comprehensive after-sales support. Whether you're in need of a quick product turnaround or ongoing technical assistance, we’re here to help.

-

OEM Services We offer OEM services, providing bespoke manufacturing to meet the specific needs of clients in various industries, ensuring maximum flexibility and product customization.

|

|

Baoji City shenAo Metal Materials Co., Ltd. was founded in 2008 and is located in the "China Titanium Valley" Shaanxi Baoji High tech Industrial Development Zone. It focuses on the research and production of non-ferrous metal composite materials, precious metal coated titanium anodes (DSA), and titanium cathode products. Based on mature bimetallic explosive welding technology and advanced active coating manufacturing process, relying on strong resources in the Chinese titanium valley industry and the processing and manufacturing capabilities for bidding for the Olympics, we accurately and timely meet customer needs and create value for customers; Leading the development of energy-saving and environmentally friendly metal composite materials products through technological innovation, and continuously improving to meet customers' demand for long-life titanium electrodes.

The company has established close partnerships with hundreds of non-ferrous metal equipment manufacturers and electrochemical application enterprises, and has been designated as a long-term high-quality supplier.

The company has established research and development, production, and marketing departments, with strict process technology quality and testing standards to ensure reliable products and fast delivery efficiency to global customers.

Our Service

We provide a variety of customized services, mainly for the followingWe provide a variety of customized services, mainly for the following:

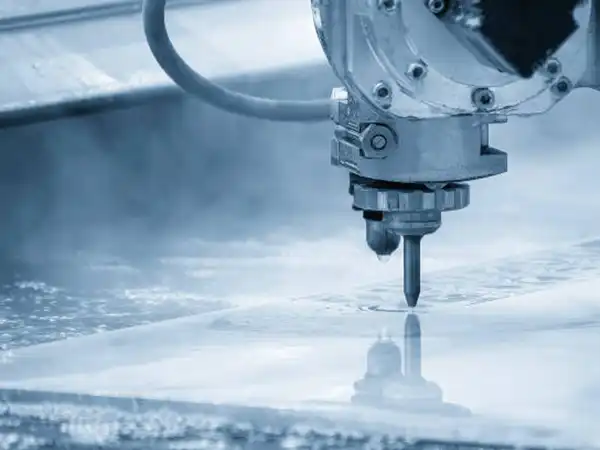

Waterjet Cutting

Laser Cutting

Welding

Plasma Welding

Polishing

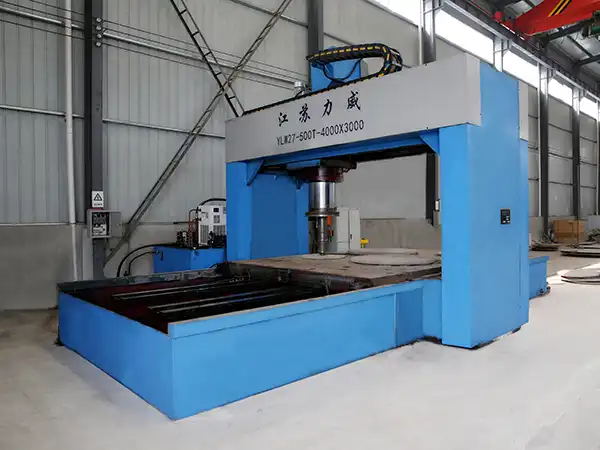

Press

Hydraulic straightening machine

Bending

Drill Press

|

|

|

|

|

|

|

|

|

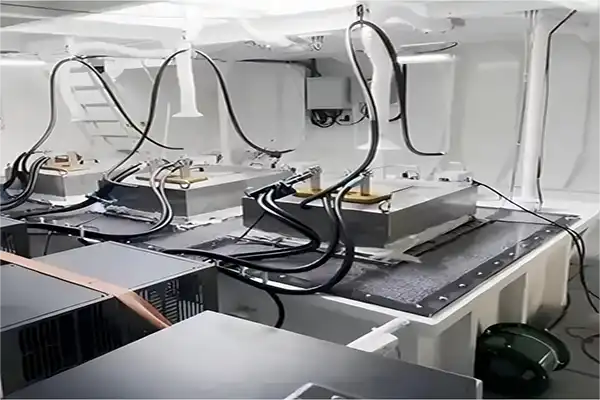

Application Industries

|

|

|

|

|

|

|

|

Our Factory

Our Patents and Honors

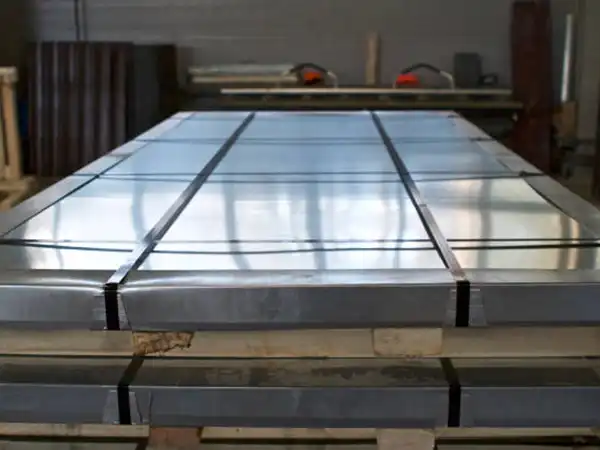

Our Packaging

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

16 Years Experience

With 16 years of experience, Baoji City ShenAo Metal Materials Co., Ltd. ensures exceptional quality and expertise in metal materials.

Perfect Service

Baoji City ShenAo Metal Materials Co., Ltd. is committed to providing perfect service, ensuring customer satisfaction and timely delivery.

Professional Knowledge

With professional knowledge in non-ferrous metals and titanium, we deliver innovative and reliable solutions to customers.

Fast Delivery

We prioritize fast delivery, ensuring timely and efficient service to meet our customers' needs.

Frequently Asked Questions (FAQs)

-

What industries use stainless steel composite plates for pressure vessels? Stainless steel composite plates are widely used in industries such as chemical processing, energy production, water treatment, marine engineering, and pharmaceuticals.

-

Can I get custom sizes for the composite plates? Yes, we offer customization in terms of thickness, dimensions, and coatings based on your specific application needs.

-

What are the advantages of using composite plates over traditional materials? The primary benefits include superior corrosion resistance, enhanced strength, and improved thermal conductivity, making composite plates ideal for high-pressure and corrosive environments.

-

How can I ensure the proper maintenance of stainless steel composite plates? Regular inspection for corrosion, particularly in high-stress areas, and maintaining an appropriate environment (temperature and chemical exposure) will prolong the life of the plates.

Contact Us

For more information or to place an order, contact us today!

Company Name: Baoji City ShenAo Metal Materials Co., Ltd.

Address: Wenquan Village Industrial Park, High-tech Zone, Baoji City

Contact Person: Wang Shujuan

Phone: +86-18729731603

Fax: +86-917-3380538

Email: zh@baojiti.com.cn

Let us provide you with the best composite materials for your pressure vessel needs!

YOU MAY LIKE